QR Kodlarının Yapısı

QR kodu (Quick response code), 1994 yılında DENSO WAVE tarafından geliştirilen yüksek hızlı okuma yapabilen bir matris 2D kodudur. 1997 yılında AIMI’nin ITS standardına ve 2000 yılında ISO/IEC standartlarına göre tescil edilmiştir.

Ayrıca, Micro QR kodu 2004 yılında JIS-X-0510 olarak standartlaştırılmıştır.

QR Kodlarının Özellikleri

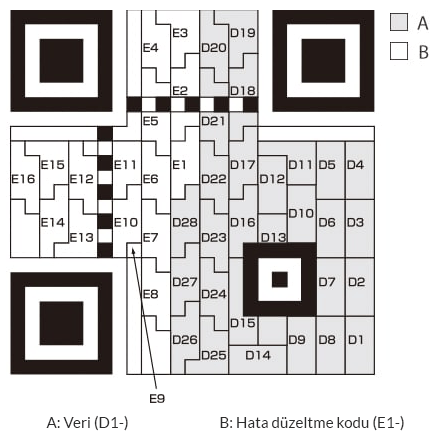

QR kodunun en küçük elemanı (siyah veya beyaz kare) “modül” olarak adlandırılır. Bir QR kodu, siyah ve beyaz modüllerin, konum algılama modellerinin, zamanlama modellerinin, hata düzeltme seviyesi ve maske numaralarını içeren format bilgilerinin, veri alanının ve hata düzeltme kodunun bir kombinasyonundan oluşur.

(Reed-Solomon kodu).

| Özellikler | |||

|---|---|---|---|

| Minimum boyut | 21 x 21 modül | ||

| Maksimum boyut | 177 x 177 modül | ||

| Maksimum veri kapasitesi | Sayısal | 7089 karakter | |

| Alfa sayısal | 4296 karakter | ||

| Kanji | 1817 karakter | ||

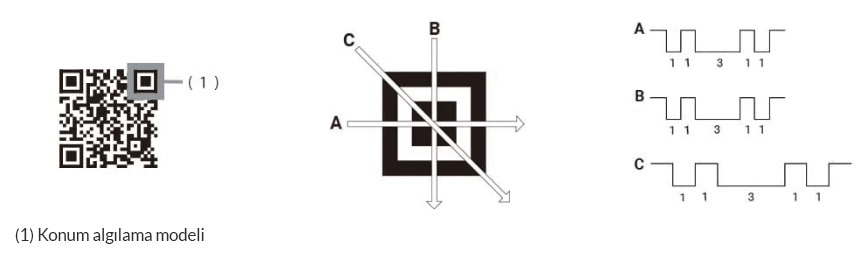

Konum algılama modelleri

Konum algılama modelleri, QR kodlarının üç köşesine yerleştirilmiştir. (Mikro QR’de bir tane vardır.) QR kodunun konumu, yüksek hızlı okumaya olanak tanıyan konum algılama modelleri sayesinde algılanır.

A, B ve C’nin herhangi bir konumundan, kodun dönüş açısını/yer değiştirmesini belirtebilmek için siyah ve beyaz modüllerin oranı 1:1:3:1:1’dir. Her yönden okunabildiği için iş verimliliğini önemli ölçüde artırır.

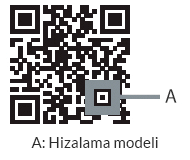

Hizalama modeli

Hizalama modeli, herhangi bir bozulma nedeniyle modüllerin yer değiştirmesi durumunda konum tespiti için kullanılır.

2. modele uygulanır

Kenar boşlukları

QR kodunu çevresindeki boşluklardır. Model 1 ve 2, dört modüllü bir marj (kenar boşluğu) gerektirirken Mikro QR kodu iki modül gerektirir.

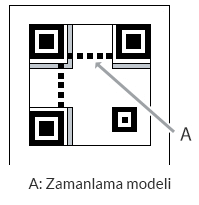

Zamanlama modeli

Beyaz ve siyah modüller, koordinatı belirleyebilmek için sıralı bir şekilde, dönüşümlü olarak düzenlenir.

Format/Biçim bilgisi

Format bilgisi, kodun hata düzeltme oranını ve maske modelini içerir. Kod çözüldüğünde ilk olarak format bilgisi okunması gerçekleşir.

Hata düzeltme kodu (Reed-Solomon kodu)

Reed-Solomon kodu, Veri matrisi (DataMatrix) kodunun bir parçası hasar gördüğünde verileri onarır.

| Hata düzeltme seviyesi | Kodun tamamında zarar görmüş alan | ||

|---|---|---|---|

| L | 7% | ||

| M | 15% | ||

| Q | 25% | ||

| H | 30% | ||

Hata düzeltme kodunun düzenlenmesi

Veri ve hata düzeltme kodu aşağıda gösterilen şekilde sıralanır. (Örnek: M seviyesinde Model 2 Sürüm 2) Konum algılama modeliyle aynı modelin görünmesini önlemek için koda bir maske uygulanır.

QR Kodlarının Özellikleri

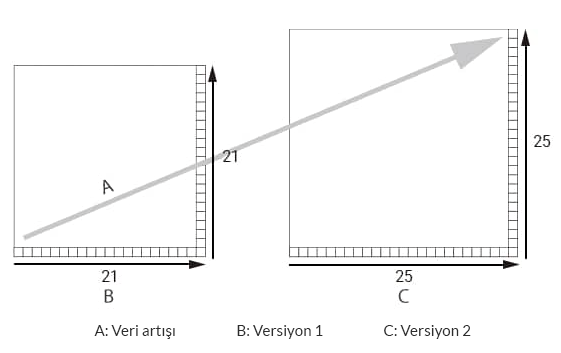

Farklı özelliklere ve veri kapasitelerine sahip QR kodları; Model 1, Model 2 ve Mikro QR olarak sınıflandırılır.

“Sürüm”, bir QR kodunun boyutunu (modül sayısını) gösterir. Sürüm arttıkça daha fazla veri içerir. (Kodun gerçek boyutu da artar.)

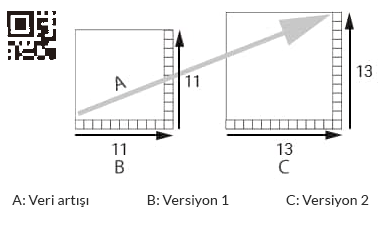

Standart sürüm 21 x 21 modüldür (MicroQR 11 x 11 modüle sahiptir) ve sürüm arttıkça her iki tarafa 4 modül (MicroQR için 2 modül) eklenir.

Model 1

Model 2

| Maksimum veri kapasitesi | |||

|---|---|---|---|

| Sayısal | 1167 karakter | ||

| Alfa sayısal | 707 karakter | ||

| Çift (İkili) | 468bayt | ||

| Kanji | 299 karakter | ||

| Maksimum veri kapasitesi | |||

|---|---|---|---|

| Sayısal | 7089 karakter | ||

| Alfa sayısal | 4296 karakter | ||

| Çift (İkili) | 2953 bayt | ||

| Kanji | 1817 karakter | ||

Mikro QR

Mikro QR’nin baskılı devre kartları gibi küçük bileşenlere basılabilmesi için boyutu küçültmek adına yalnızca bir konum algılama modeli içerir. Minimum modül sayısı 11 x 11’dir.

Mikro QR kodları, 35 veya daha az sayıda karakter kaldırabilen uygulamalar için doğrusal barkodlara yer kazandıran bir alternatiftir.

| Maksimum veri kapasitesi | |||

|---|---|---|---|

| Sayısal | 35 karakter | ||

| Alfa sayısal | 21 karakter | ||

| Çift (İkili) | 15 bayt | ||

| Kanji | 19 karakter | ||

QR kod boyutu nasıl belirlenir?

QR kodunun boyutu, bir modülün sürümüne ve boyutuna göre belirlenir.

(1) Sürümü belirleyin

Veri içeriğine, karakter tipine ve hata düzeltme oranına göre bir sürüm seçin.

Maksimum giriş karakteri sayısı için aşağıya bakın.

(2) Modül boyutunu belirleyin

Yazıcının çözünürlüğünü ve tarayıcının performansını göz önünde bulundurarak modül boyutunu belirleyin.

(3) QR kodunun boyutu belirlenir

QR kodunun gerçek boyutu, modül sayısı ile yazdırılabilir modülün boyutu çarpılarak belirlenir. QR kodunun gerektirdiği alanı belirlemek için kenar boşlukları eklenir. Model 1 ve 2, 4 modül gerektirirken Mikro QR, her iki tarafta kenar boşluğu olarak 2 modül gerektirir.

Modül boyutu 0.25mm olduğu zaman ,

QR kodunun boyutları aşağıdaki gibidir:

Sürüm 1 için 5,25 x 5,25 mm (21 x 21)

Sürüm 4 için 8,25 x 8,25 mm (33 x 33)

Kenar boşlukları dahil gereken alanlar aşağıdaki gibidir:

Sürüm 1 için 7,25 x 7,25 mm (29 x 29)

1Sürüm 4 için 10,25 x 10,25 mm (41 x 41)

Her sürümün veri kapasitesi

Model

| Sürüm (Modül numarası) | Sayısal | Alfa sayısal | Çift (İkili) | Kanji | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | M | Q | H | L | M | Q | H | L | M | Q | H | L | M | Q | H | |

| 1(21) | 41 | 34 | 27 | 17 | 25 | 20 | 16 | 10 | 17 | 14 | 11 | 7 | 10 | 8 | 7 | 4 |

| 2(25) | 77 | 63 | 48 | 34 | 47 | 38 | 29 | 20 | 32 | 26 | 20 | 14 | 20 | 16 | 12 | 8 |

| 3(39) | 127 | 101 | 77 | 58 | 77 | 61 | 47 | 35 | 53 | 42 | 32 | 24 | 32 | 26 | 20 | 15 |

| 4(33) | 187 | 149 | 111 | 82 | 114 | 90 | 67 | 50 | 78 | 62 | 46 | 34 | 48 | 38 | 28 | 21 |

| 5(37) | 255 | 202 | 144 | 106 | 154 | 122 | 87 | 64 | 106 | 84 | 60 | 44 | 65 | 52 | 37 | 27 |

| 6(41) | 322 | 255 | 178 | 139 | 195 | 154 | 108 | 84 | 134 | 106 | 74 | 58 | 82 | 65 | 45 | 36 |

| 7(45) | 370 | 293 | 207 | 154 | 224 | 178 | 125 | 93 | 154 | 122 | 86 | 64 | 95 | 75 | 53 | 39 |

| 8(49) | 461 | 365 | 259 | 202 | 279 | 221 | 157 | 122 | 192 | 152 | 108 | 84 | 118 | 93 | 66 | 52 |

| 9(53) | 552 | 432 | 312 | 235 | 335 | 262 | 189 | 143 | 230 | 180 | 108 | 130 | 141 | 111 | 80 | 60 |

| 10(57) | 652 | 513 | 364 | 288 | 395 | 311 | 221 | 174 | 271 | 213 | 151 | 119 | 167 | 131 | 93 | 74 |

| 11(61) | 772 | 604 | 427 | 331 | 468 | 366 | 259 | 200 | 321 | 251 | 177 | 137 | 198 | 155 | 109 | 85 |

| 12(65) | 883 | 691 | 489 | 374 | 535 | 419 | 296 | 227 | 367 | 287 | 203 | 155 | 226 | 177 | 125 | 96 |

| 13(69) | 1022 | 796 | 580 | 427 | 619 | 483 | 352 | 259 | 425 | 331 | 241 | 177 | 262 | 204 | 149 | 109 |

| 14(73) | 1101 | 871 | 621 | 468 | 667 | 528 | 376 | 283 | 458 | 362 | 258 | 194 | 282 | 223 | 159 | 120 |

| 15(77) | 1250 | 991 | 703 | 530 | 758 | 600 | 426 | 321 | 520 | 412 | 292 | 220 | 320 | 254 | 180 | 136 |

| 16(81) | 1408 | 1082 | 775 | 602 | 854 | 656 | 470 | 365 | 586 | 450 | 322 | 250 | 361 | 277 | 198 | 154 |

| 17(85) | 1548 | 1212 | 876 | 674 | 938 | 734 | 531 | 408 | 644 | 504 | 364 | 280 | 397 | 310 | 224 | 173 |

Mikro QR

| Sürüm | Hata düzeltme | Sayısal | Alfa sayısal | Çift (İkili) | Kanji |

|---|---|---|---|---|---|

| M1(11) | Hata düzeltme | 5 | – | – | – |

| M2(13) | L | 10 | 6 | – | – |

| M | 7 | 5 | – | – | |

| M3(15) | L | 23 | 14 | 9 | 6 |

| M | 18 | 11 | 7 | 4 | |

| M4(17) | L | 35 | 21 | 15 | 9 |

| M | 30 | 18 | 13 | 8 | |

| Q | 21 | 13 | 9 | 5 |

Yukarıda bulunan tablodaki her karakter sayısı, girilebilecek maksimum karakter sayısını gösterir.

Bununla birlikte, veriler yukarıdaki tabloda gösterilenlerden daha az karakter içerse bile, veri bileşenine bağlı olarak sürümün boyutu büyür (örneğin, rakamlar ve sembollerin kombinasyonu veya büyük ve küçük harflerin kombinasyonu).