Endüstriyel Kamera Seçiminde Dikkat Edilmesi Gerekenler

Bir endüstriyel görüntü işleme sistemi kullanırken, donanım seçimleri, uygulama gereksinimleri ve istenen inceleme detaylarına göre belirlenmelidir. Bu yazımızda, en uygun kamera, lens, aydınlatma, kontrolör ve diğer gerekli aksesuarların nasıl seçileceğini sizler için özetledik.

Alan kameraları dört ana gruba ayrılır:

- Yüksek çözünürlüklü modeller

- Yüksek hızlı modeller

- Standart modeller

- Kompakt modeller

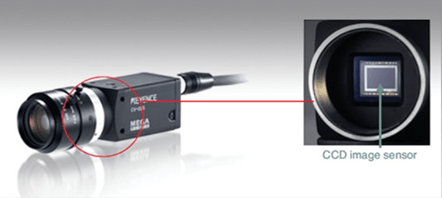

Her modelin renkli veya monokrom olma özelliği vardır. Doğru kamera seçimi, aşağıda özetlenen uygulamaya bağlıdır.

1) Doğruluk gereksinimlerini karşılayacak piksel sayısını belirleyin.

Ölçüm uygulamalarında, piksel başına düşen çözünürlük, istenen ölçüm toleransının 1/10’u kadar olmalıdır.

Varlık/yokluk kontrollerinde, algılanması gereken en küçük objenin görüş alanında 500 piksel veya daha fazla olması gereklidir.

Kod okuma uygulamalarında, okunacak kodun boyutu, görüş alanının en az 3/4’ünü kapsayacak şekilde belirlenmelidir. Bu kriterler, kararlı ve güvenilir bir görüntü işleme süreci için kritik öneme sahiptir.

2) Uygulamanın ihtiyaçlarına göre aktarım hızını seçin.

Yüksek hızlı üretim hatlarında, kameranın görüntü aktarım süresi, algılanabilecek ürün sayısını doğrudan etkiler.

Dakikada 200 adet ve üzeri görsel kontrol gerektiren uygulamalarda, yüksek hızlı kameraların kullanımı büyük önem taşır.

3) Kurulum alanına uygun kamera boyutunu belirleyin.

Kameranın monte edileceği makine veya üretim hattında alan kısıtlıysa, kompakt kamera tercih edilmelidir. Sınırlı montaj alanlarında optimum konumlandırma sağlamak, sistemin performansını artıracaktır.

4) İnceleme türüne göre renkli veya siyah/beyaz endüstriyel kamera seçin.

Ölçüm uygulamalarında genellikle siyah/beyaz kameralar tercih edilir, çünkü tek renkli sensörler daha yüksek kontrast sağlayarak hassas ölçümler yapılmasına olanak tanır. Ancak, renk farklılıklarının kritik olduğu uygulamalarda, renkli kameralar kullanılarak daha hassas algılama gerçekleştirilebilir.

Linescan Kameralar ve Endüstriyel 3D kameralar

KEYENCE, ince veya küçük kusurları tespit edebilen çizgi tarama kameraları da dahil olmak üzere çeşitli endüstriyel kamera çözümleri sunmaktadır. Ayrıca, tek bir görüntü işleme sisteminde 2D ve 3D eş zamanlı algılama yapabilen 3D özellikli endüstriyel kameralar ile yüksek hassasiyetli inceleme imkanı sağlamaktadır.

Lens Seçme

Endüstriyel kamera sistemleri için doğru lensi seçerken dikkate alınması gereken çeşitli faktörler vardır. Görüş alanı (FOV) ve çalışma mesafesi (WD), görüntü yakalama için uygun lens odak mesafesinin belirlenmesini sağlar. Lens seçiminde ayrıca alan derinliği (odak derinliği aralığı) ve kontrast önemli kriterler arasındadır. Genel seçim prosedürü aşağıda özetlenmiştir.

1️⃣ Odak mesafesini belirleyin: Görüntü yakalama boyutuna (FOV) ve kurulum mesafesi gereksinimlerine (WD) göre uygun odak mesafesini seçin.

2️⃣ Alan derinliği gereksinimini değerlendirin: Hedefin yüksekliği ve geometrik yapısına bağlı olarak gerekli alan derinliğini belirleyin. Değişken yükseklikte yüzeylere veya karmaşık şekillere sahip ürünler daha fazla alan derinliği gerektirir. Çalışma mesafesi arttıkça, odak uzaklığı azaldıkça ve diyafram daraldıkça alan derinliği artar.

3️⃣ Lens çözünürlüğünü seçin: İnceleme doğruluğu ve kontrast gereksinimlerine göre yüksek çözünürlüklü bir lens veya standart bir lens tercih edin. Yüksek çözünürlüklü lensler, ince detayların algılanmasını ve keskin görüntüler elde edilmesini sağlar.

Aydınlatma seçimi

Aydınlatma yönü, rengi ve türü; hedef özellikleri, inceleme gereksinimleri ve çevresel koşulların bir kombinasyonu dikkate alınarak belirlenmelidir.

Aşağıda, genel bir aydınlatma seçim süreci özetlenmiştir:

1️⃣ Aydınlatma yönünü belirleyin: İnceleme amacı, hedefin malzeme yapısı ve geometrisine bağlı olarak uygun aydınlatma türünü seçin:

- Aynasal yansıma: Parlak ve düzgün yüzeylerde detayları vurgulamak için kullanılır.

- Dağınık yansıma: Pürüzlü veya düzensiz yüzeylerde homojen aydınlatma sağlamak için tercih edilir.

2️⃣ Aydınlatmanın şekline ve boyutuna karar verin:

Önceki adımda belirlediğiniz yansıma türüne göre uygun aydınlatma seçeneğini tercih edin:

- Aynasal yansıma için: Koaksiyel aydınlatma, ring aydınlatma veya bar aydınlatma kullanın.

- Dağınık yansıma için: Düşük açılı (low-angle) aydınlatma, ring aydınlatma veya bar aydınlatma tercih edin.

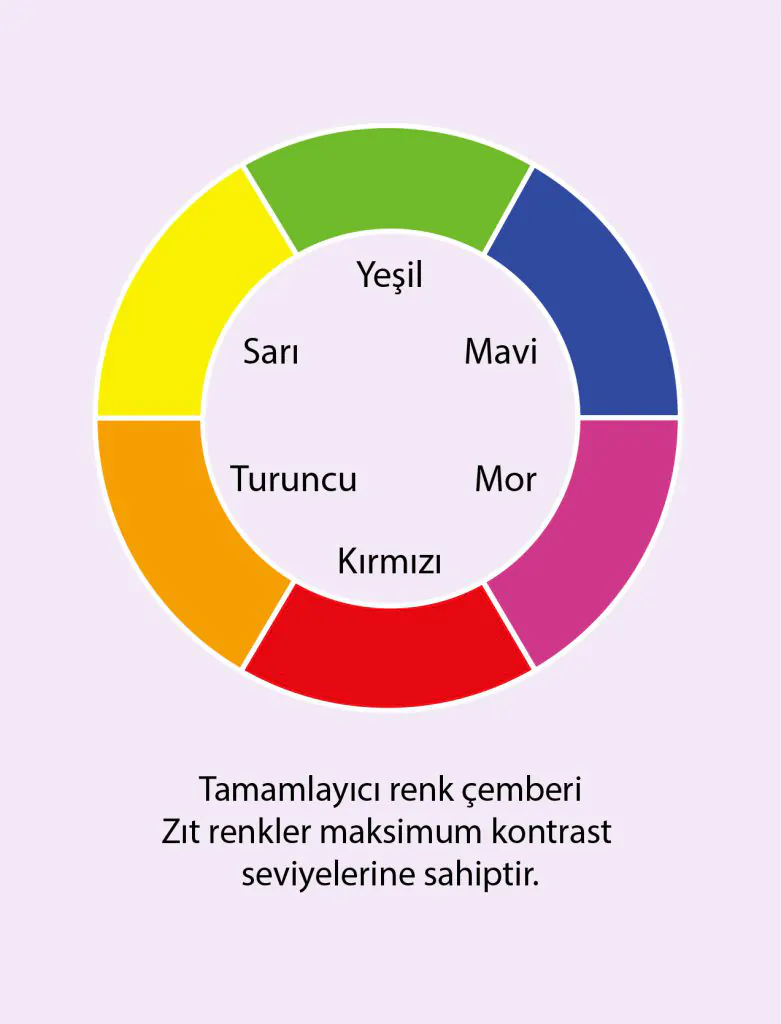

3️⃣ Aydınlatmanın rengine (dalga boyu) karar verin:

- Renkli kamera incelemeleri için beyaz aydınlatma genellikle standarttır.

- Tek renkli kamera incelemeleri için ise renkli aydınlatma, tamamlayıcı renkler veya dalga boyları kullanılarak görüntü kontrastı artırılabilir ve daha net sonuçlar elde edilebilir.

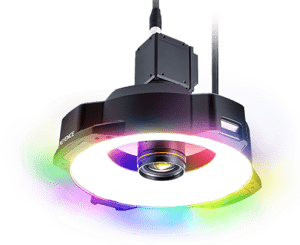

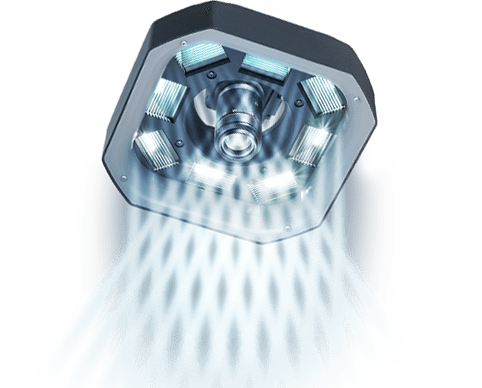

Çok işlevli, yüksek performanslı aydınlatma üniteleri

Birden çok yöne, farklı dalga boylarına ve çeşitli desenlere ışık yansıtabilen çok işlevli, yüksek performanslı bir aydınlatma ünitesinin kullanımı ve yeni denetim algoritmaları, geleneksel tek işlevli aydınlatmanın karşılaştığı çeşitli sorunları çözebilir. Parlama giderme, desenli arka plan üzerinde sadece düzensizliklerin çıkarılması, ince renk farklılıklarının ayırt edilmesi, 3D denetimleri ve çoklu denetim öğeleriyle verimli performans gibi zorlu denetim gereksinimlerini karşılamak için gelişmiş aydınlatma sistemleri tercih edilebilir.