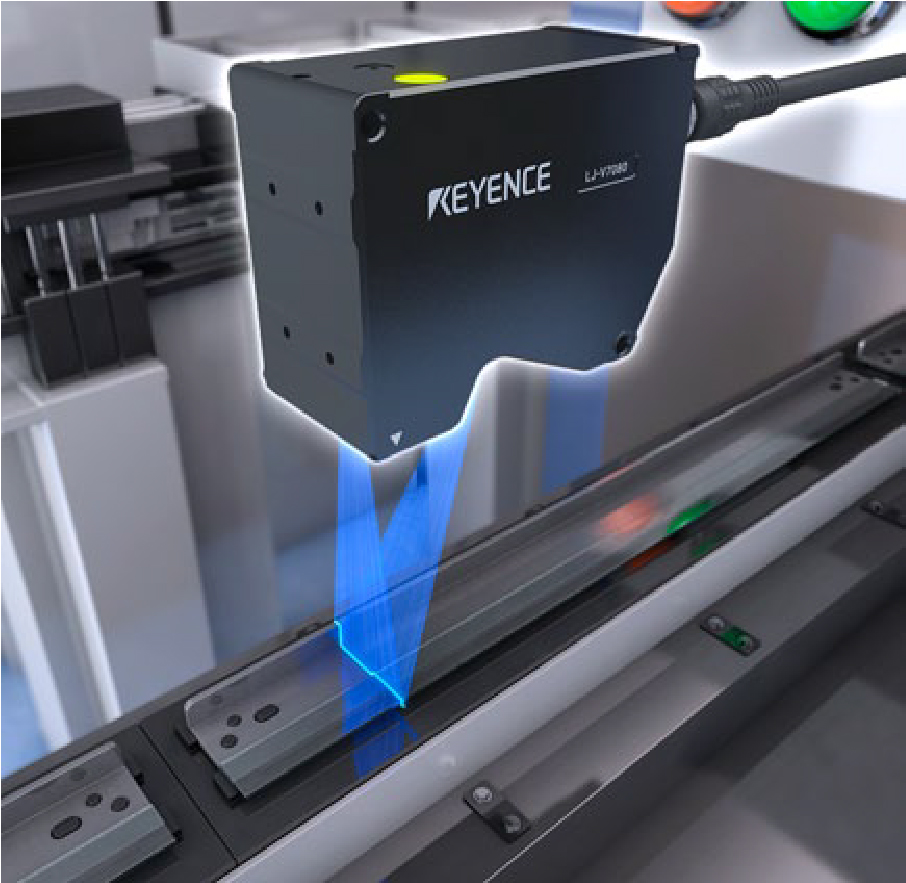

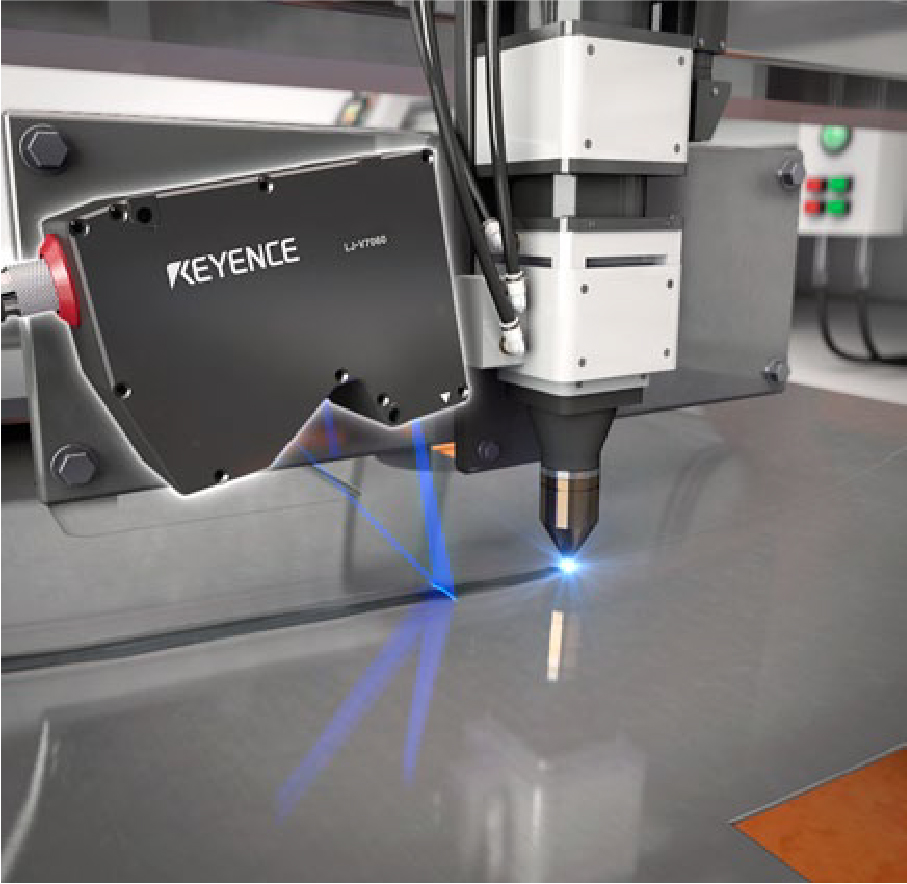

KEYENCE LJ-V 7000 2D Lazer Profil Sensörleri

KEYENCE LJ-V 7000 Her tür ve şekildeki ürünün ölçümünü gerçekleştirebilen yüksek hızlı lazer profil sensörü

- Saniyede 64.000 profil ile dünyanın en hızlısı, 12.800.000 nokta/sn örnekleme

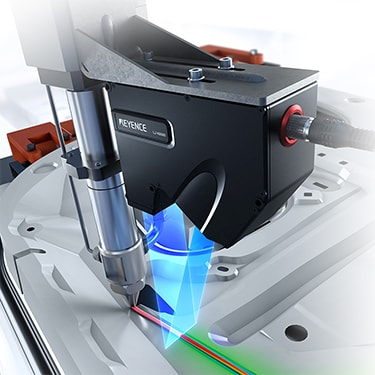

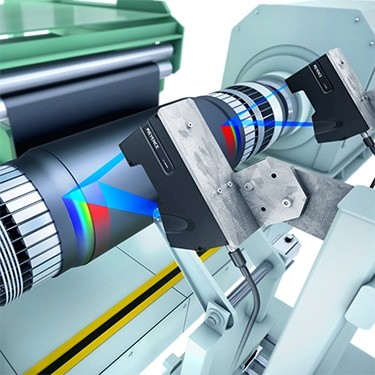

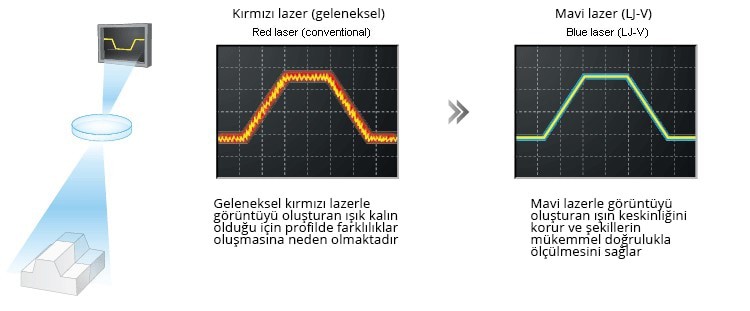

- Mavi lazer optik sistem

- 74 farklı ölçüm modu

- Maks. 64kHz hızda sürekli profil veri çıkışı

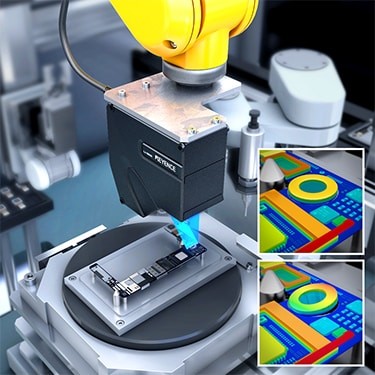

- Kolay 3D görüntüleme modu

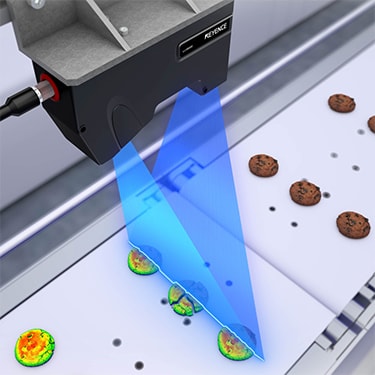

2D Ölçüm ve Algılama Çözümleri

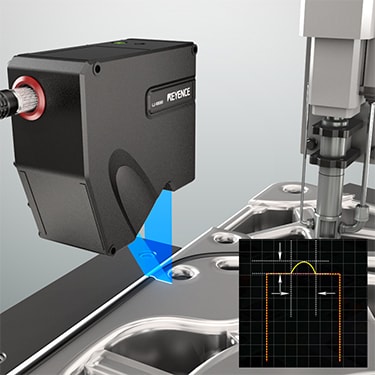

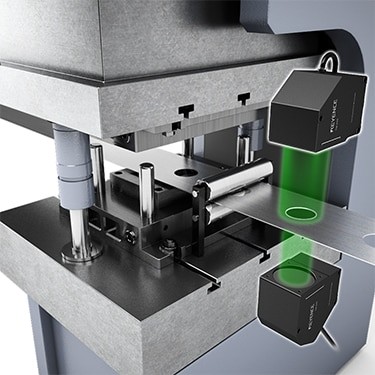

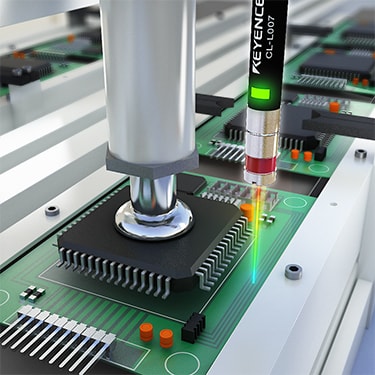

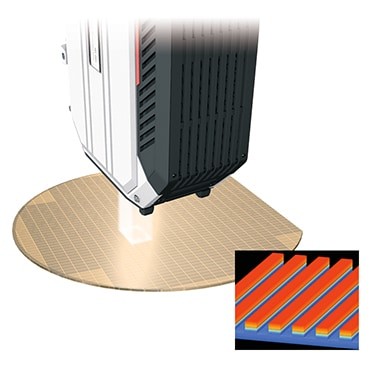

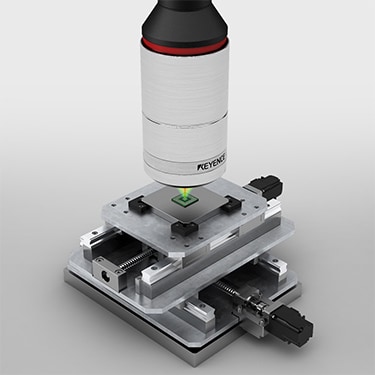

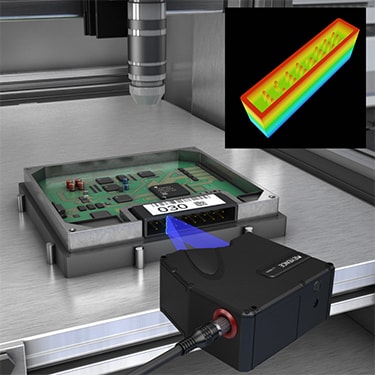

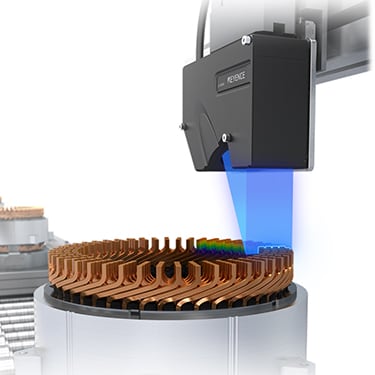

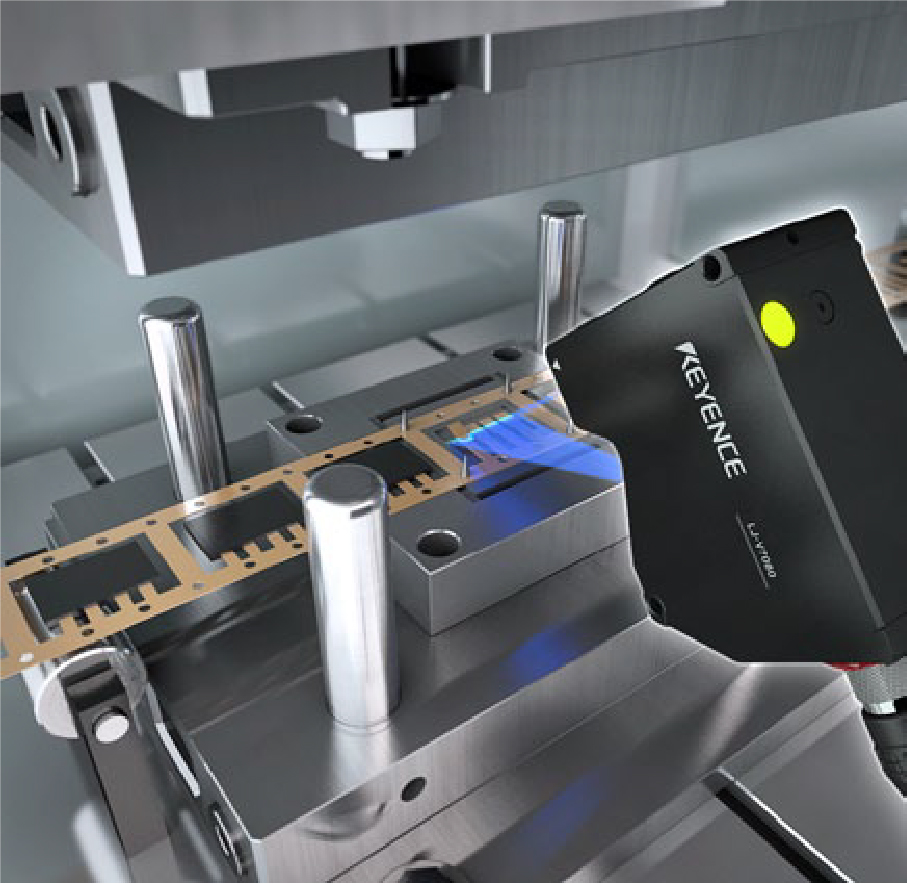

Terminal Yükseklik Ölçümü

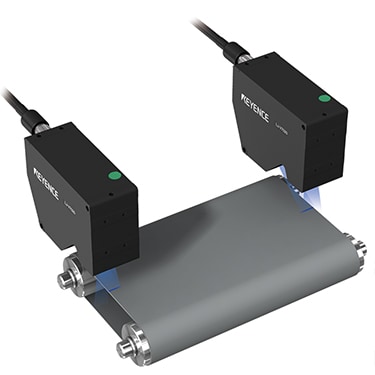

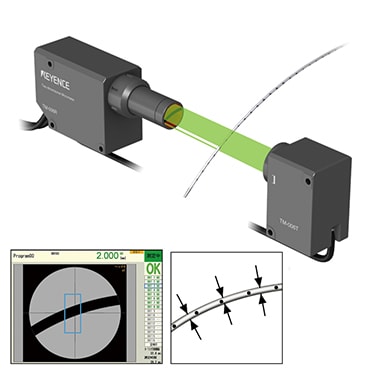

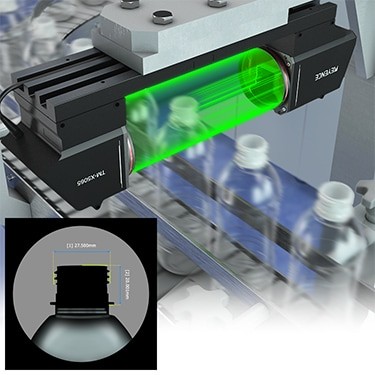

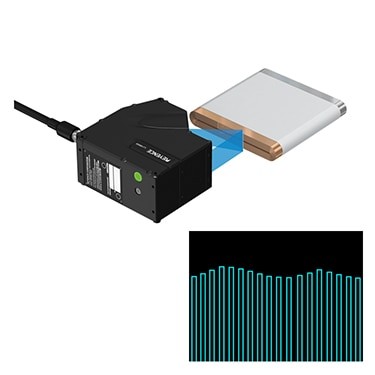

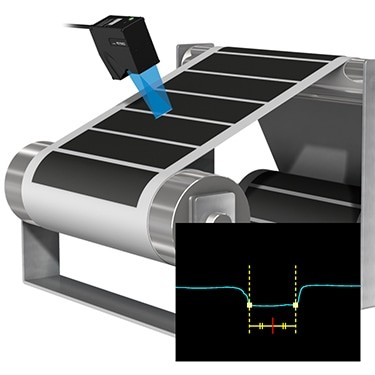

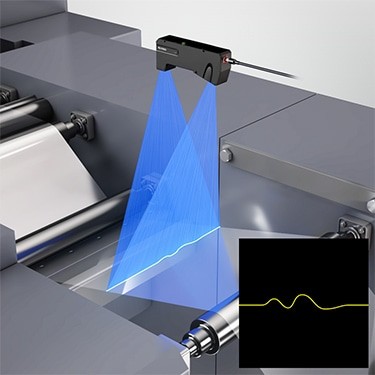

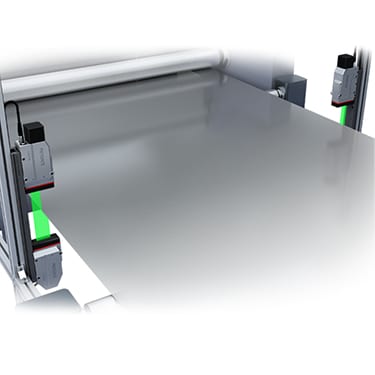

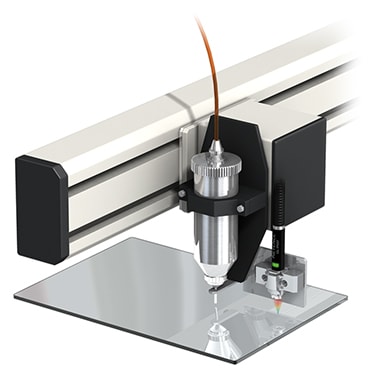

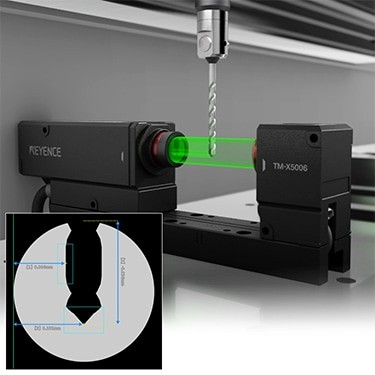

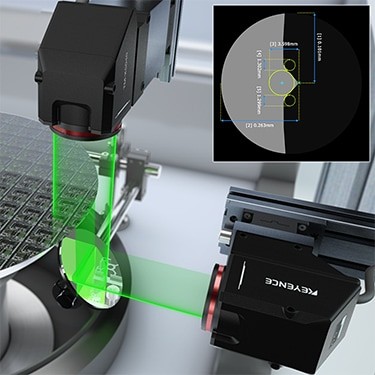

Genişlik ve Pozisyon Kontrolü

Montaj Kontrol

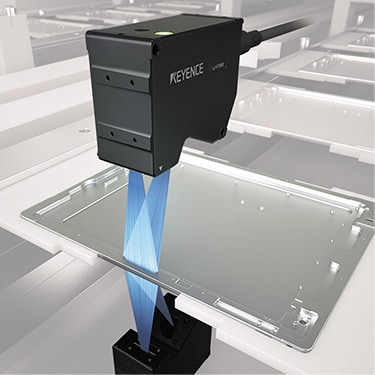

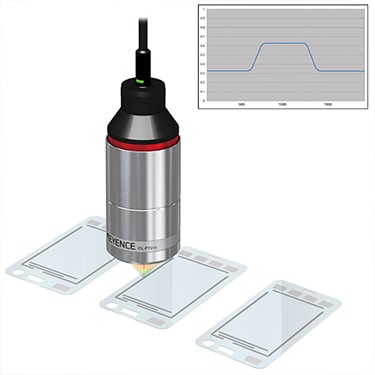

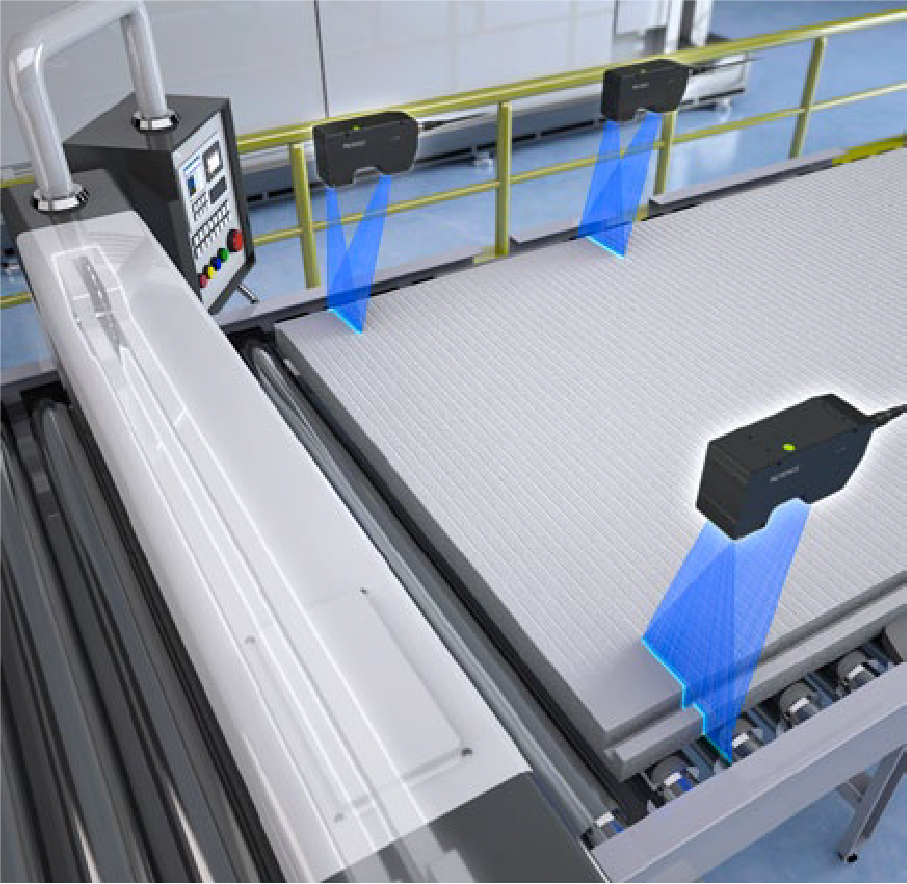

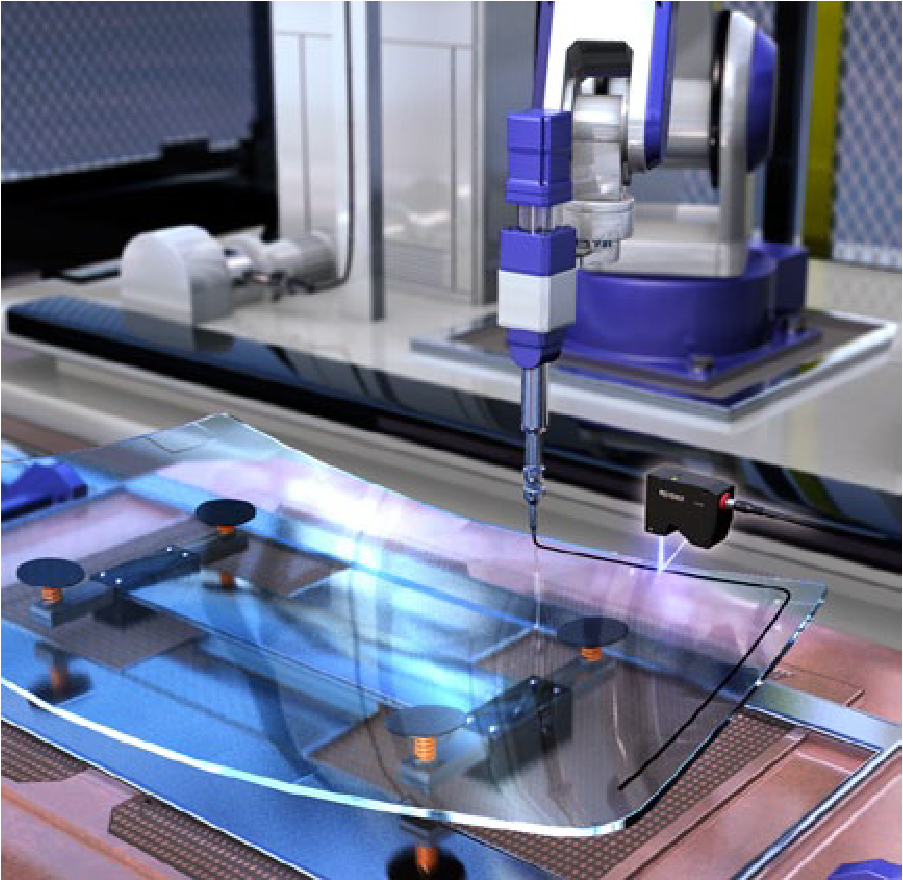

Düzlemsellik Kontrolü

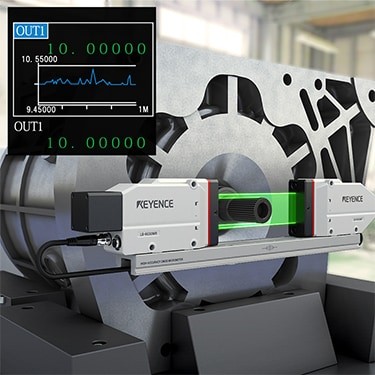

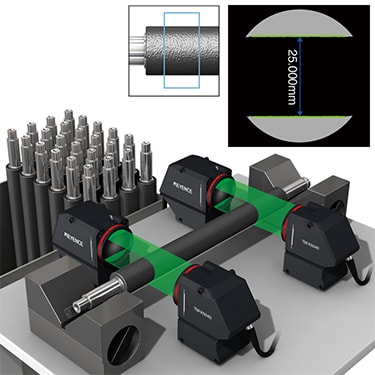

Profil Ölçümü

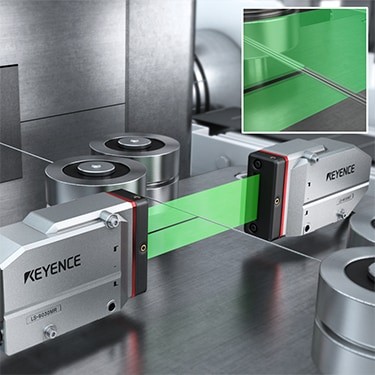

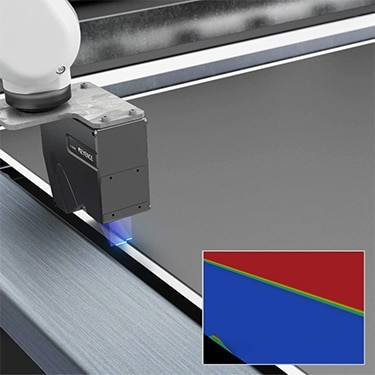

Vuruk/Çizik Kontrolü

Özellikler

Kullanıcı için kolay konfigürasyon

Ayarlar yalnızca 3 adımda gerçekleştirilebilir. Bu hem tecrübeli kullanıcılar hem de yeni başlayanlar için kolay yapılandırma sağlar.

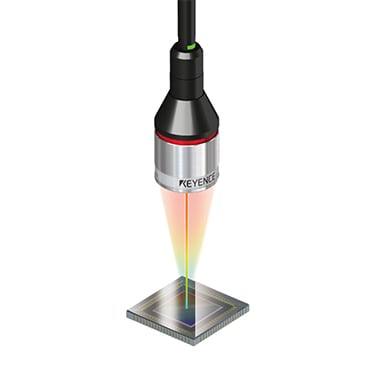

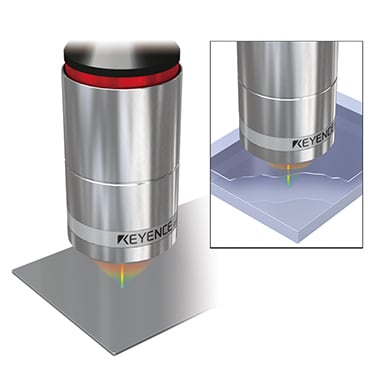

LJ-V7000 serisi dünyanın ilk mavi lazerli 2D lazer deplasman sensörüdür. 2D Ernostar lens için maksimum limit olan 405 nm dalgaboyu kısa mesafeli lazeri odaklayarak, ışık alma elemanı üzerinde keskin bir ışın demeti oluşturur. Bu sayede tutarlı ve yüksek hassasiyetli bir profil oluşturur. Ayrıca, lazerin alınan ışık yoğunluğu güvenlik için arttırılmıştır. Böylece, algılanması zor hedeflerde tutarlı ve doğru ölçüm yapılabilir.

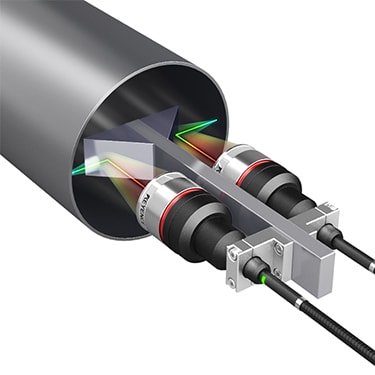

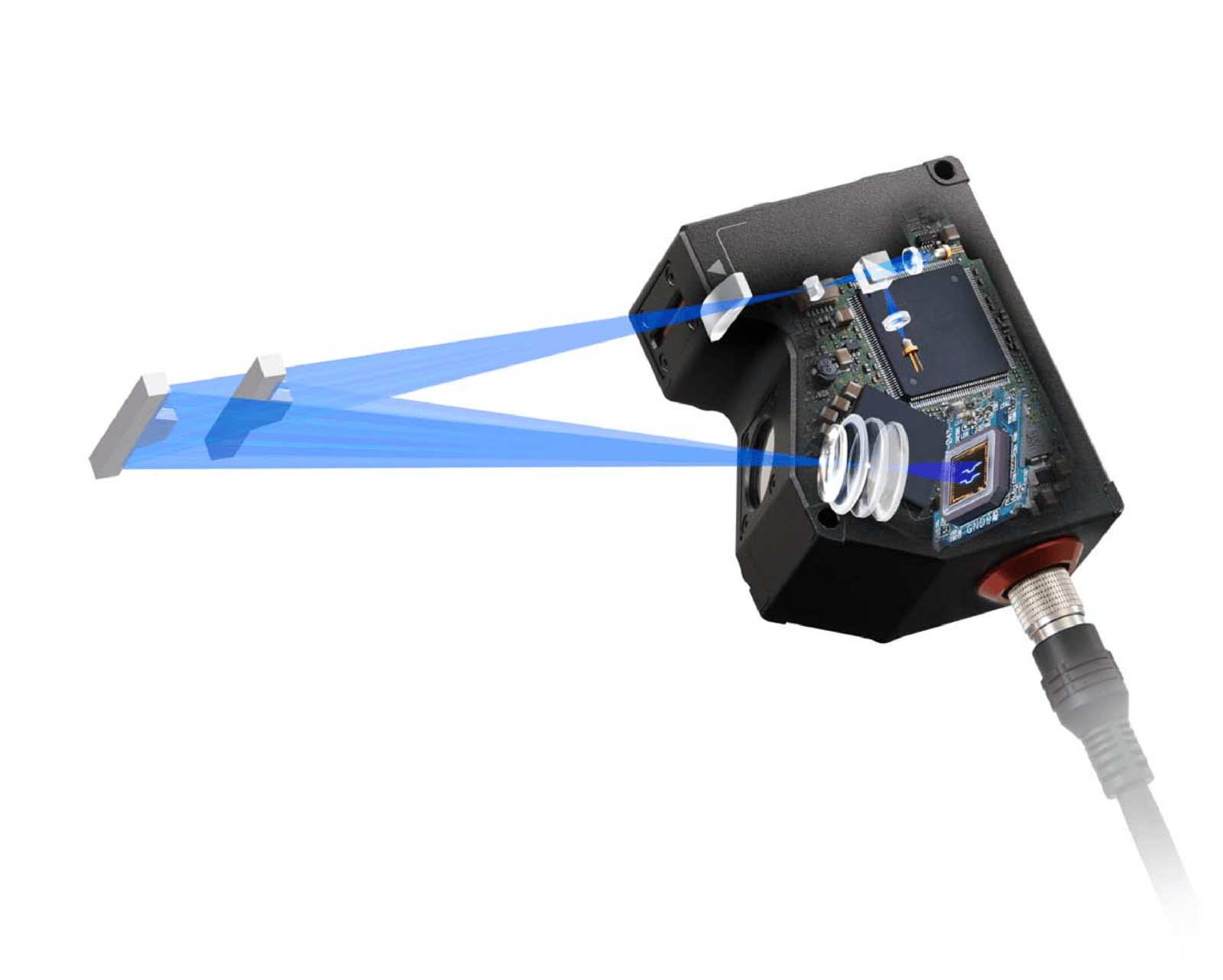

Ölçüm prensibi

Lazer ışığı silindirik lens tarafından yatay olarak yöneltilir ve hedef üzerinde dağılarak yansır. Bu yansıyan ışık HSE3-CMOS’da biçimlendirilir, pozisyon ve şekildeki değişiklikler algılanarak, deplasman ve şekillerin ölçümü gerçekleşir.

2) Yarı iletken lazerler

3) GP64 işlemci

4) 2D Ernoster lens

5) HSE3-CMOS

Geleneksel cihazlardan 240 kat daha hızlı

64.000 profil/sn. örnekleme 12.800.000 nokta/sn.

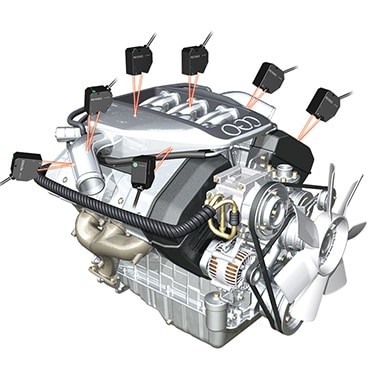

LJ-V-7000 serisi dünyanın en hızlı örnekleme hızına sahiptir. 2D lazer ölçüm pazarındaki diğer cihazlar bu hızın yanına bile yaklaşamazlar. Bir üretim hattında ilerleyen ürünlerin şekillerini ultra yüksek hızda, yüksek çözünürlükte ve ürün atlamadan ölçebilie. Örneğin; 6,4 m/s ve 0.1 mm aralıkta hareket eden hedefleri ölçebilir. LJ-V7000 serisi, normal olmayan ya da hatalı olan alanların geçişine izin vermez.

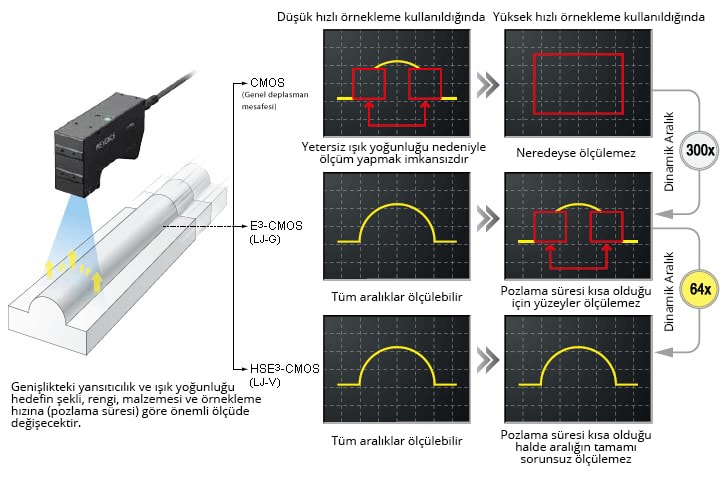

Geleneksel cihazlardan 64 kat geniş dinamik aralık

Yüksek yanıtlama kapasitesi ve algılama tutarlılığı

Normal şartlar altında algılama tutarlılığı hız ile ters orantılıdır. LJ-V7000 serisi ise hem hız hem de tutarlılık açısından gelişmiştir. Siyah yüzeylerde ya da düşük yansımalı metal yüzeylerin aynı optik eksende bir arada bulunduğu durumlarda bile şekiller doğru ölçülür.

Ultra yüksek hız ve yüksek tutarlılığa sahip gelişmiş teknoloji

LJ-V7000 Serisi yeni geliştirilen HSE3-CMOS sensöre sahiptir. Arttırılmış hıza ek olarak, geleneksel E3-CMOS’a göre dinamik aralık güçlendirilmiştir. 64 kHz’lik (15,6 µs) son derece kısa pozlama süresi ile siyah zeminlerden (düşük yansıma) cilalı yüzeylere (yüksek yansıma) kadar çok sayıda farklı yüzeyde doğru ölçüm yapılabilmesi mümkün olmaktadır.

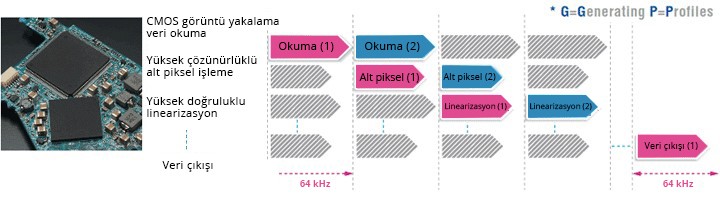

GP64 - İşlemci-64kHz ultra yüksek hızlı ölçüm

Yeni tasarladığımız mikroçip ultra yüksek hızlı işlem sağlamakla birlikte, CMOS görüntü verisini okuyabilmekte, yüksek çözünürlüklü alt piksel işleme, yüksek hassasiyetli linearizasyon ve veri çıkışı gibi işlemleri gerçekleştirebilmektedir. Bu da, yüksek hızda hareket eden nesnelerin ölçümüne imkan sağlar.

Geleneksel modeller 6,4 m/s hızla hareket eden 24,3 mm eğimli hedefleri ölçemiyordu. LJ-V 6,4 m/s hızla hareket eden 0,1 mm eğimli hedeflerin profillerini ölçebilir.

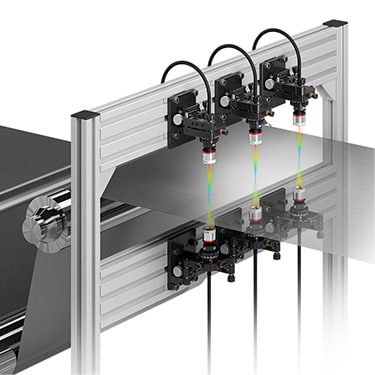

Tek bir cihaz ile her türlü ölçüm yapılabilir.

74 Farklı Ölçüm Modu

13 ölçüm detayı ve 7 ölçüm hedefi özelliği ile bu cihaz toplamda 74 farklı ölçüm yapabilir. Tek bir cihaz çok geniş bir ölçüm yelpazesi sunarak, tek bir atış bile kaçırmadan müşteri taleplerine cevap verir.

- LJ-V7020

- LJ-V7060

- LJ-V7060K

- LJ-V7080

- LJ-V7200

- LJ-V7300

- LJ-V7001P

|

Model |

LJ-V7020 * 1 |

|||

|

Installation condition |

Diffuse reflection |

|||

|

Reference distance |

20mm |

|||

|

Measurement range |

Z axis (height) |

± 2.6mm (FS = 5.2mm) |

||

|

X axis (width) |

NEAR side |

6.5mm |

||

|

Reference distance |

7mm |

|||

|

FAR side |

7.5mm |

|||

|

light source |

type |

Blue semiconductor laser |

||

|

wavelength |

405nm (visible light) |

|||

|

Laser class |

Class 2 M laser product * 2 |

|||

|

output |

10mW |

|||

|

Spot shape (reference distance) |

Approximately 14 mm x 35 µm |

|||

|

Repeat accuracy |

Z axis (height) |

0.2µm * 4 * 5 |

||

|

X-axis (width) |

2.5µm * 4 * 6 |

|||

|

Straightness |

Z axis (height) |

± 0.1% of FS * 7 |

||

|

Profile data interval |

X-axis (width) |

10µm |

||

|

Sampling cycle (trigger interval) |

Fastest 16µs (high-speed mode), fastest 32µs (high-performance mode) * 8 |

|||

|

Temperature characteristics |

0.01% of FS / ℃ |

|||

|

Environmental resistance |

Protective structure |

IP67 (IEC60529) * 9 |

||

|

Ambient illuminance used |

Incandescent lamp: 10,000 lux or less * 10 |

|||

|

Operating ambient temperature |

0 to + 45 ℃ * 11 |

|||

|

Operating ambient humidity |

20-85% RH (no condensation) |

|||

|

Vibration resistant |

10-57 Hz, double amplitude 1.5 mm, X, Y, Z 3 hours in each direction |

|||

|

Impact resistance |

15 G / 6 ms |

|||

|

Material |

Aluminum |

|||

|

mass |

About 410 g |

|||

|

* 1 W polarization function cannot be used. |

||||

|

Model |

LJ-V7060 |

|||

|

Installation condition |

Diffuse reflection |

|||

|

Reference distance |

60mm |

|||

|

Measurement range |

Z axis (height) |

± 8mm (FS = 16mm) |

||

|

X axis (width) |

NEAR side |

13.5mm |

||

|

Reference distance |

15mm |

|||

|

FAR side |

||||

|

light source |

type |

Blue semiconductor laser |

||

|

wavelength |

405nm (visible light) |

|||

|

Laser class |

Class 2 M laser product * 1 |

|||

|

output |

10mW |

|||

|

Spot shape (reference distance) |

Approximately 21 mm x 45 µm |

|||

|

Repeat accuracy |

Z axis (height) |

0.4µm * 3 * 4 |

||

|

X-axis (width) |

5µm * 3 * 5 |

|||

|

Straightness |

Z axis (height) |

± 0.1% of FS * 6 |

||

|

Profile data interval |

X-axis (width) |

20µm |

||

|

Sampling cycle (trigger interval) |

Fastest 16µs (high-speed mode), fastest 32µs (high-performance mode) * 7 |

|||

|

Temperature characteristics |

0.01% of FS / ℃ |

|||

|

Environmental resistance |

Protective structure |

IP67 (IEC60529) * 8 |

||

|

Ambient illuminance used |

Incandescent lamp: 10,000 lux or less * 9 |

|||

|

Operating ambient temperature |

0 to +45 ℃ * 10 |

|||

|

Operating ambient humidity |

20-85% RH (no condensation) |

|||

|

Vibration resistant |

10-57 Hz, double amplitude 1.5 mm, X, Y, Z 3 hours in each direction |

|||

|

Impact resistance |

15 G / 6 ms |

|||

|

Material |

Aluminum |

|||

|

mass |

About 450 g |

|||

|

* 1 Do not look directly at the beam using an optical instrument (for example, a loupe, magnifying glass, microscope, telescope, binoculars, etc.). Observing the laser output with an optical instrument can be dangerous to the eyes. |

||||

|

Model |

LJ-V7060K |

|||

|

Installation condition |

Specular reflection |

|||

|

Reference distance |

54.6mm |

|||

|

Measurement range |

Z axis (height) |

± 7.6mm (FS = 15.2mm) |

||

|

X axis (width) |

NEAR side |

8mm |

||

|

Reference distance |

14mm |

|||

|

FAR side |

8mm |

|||

|

light source |

type |

Blue semiconductor laser |

||

|

wavelength |

405nm (visible light) |

|||

|

Laser class |

Class 2 laser products |

|||

|

output |

4.8mW |

|||

|

Spot shape (reference distance) |

Approximately 21 mm x 45 µm |

|||

|

Repeat accuracy |

Z axis (height) |

0.4µm * 2 * 3 |

||

|

X-axis (width) |

5µm * 2 * 4 |

|||

|

Straightness |

Z axis (height) |

± 0.1% of FS * 5 |

||

|

Profile data interval |

X-axis (width) |

20µm |

||

|

Sampling cycle (trigger interval) |

Fastest 16µs (high-speed mode), fastest 32µs (high-performance mode) * 6 |

|||

|

Temperature characteristics |

0.01% of FS / ℃ |

|||

|

Environmental resistance |

Protective structure |

IP67 (IEC60529) * 7 |

||

|

Ambient illuminance used |

Incandescent lamp: 10,000 lux or less * 8 |

|||

|

Operating ambient temperature |

0 to + 45 ℃ * 9 |

|||

|

Operating ambient humidity |

20-85% RH (no condensation) |

|||

|

Vibration resistant |

10-57 Hz, double amplitude 1.5 mm, X, Y, Z 3 hours in each direction |

|||

|

Impact resistance |

15 G / 6 ms |

|||

|

Material |

Aluminum |

|||

|

mass |

About 450 g |

|||

|

* 1 Classification is carried out according to IEC60825-1 according to Laser Notice No.50 of FDA (CDRH). |

||||

|

Model |

LJ-V7080 |

|||

|

Installation condition |

Diffuse reflection |

|||

|

Reference distance |

80mm |

|||

|

Measurement range |

Z axis (height) |

± 23mm (FS = 46mm) |

||

|

X axis (width) |

NEAR side |

25mm |

||

|

Reference distance |

32mm |

|||

|

FAR side |

39mm |

|||

|

light source |

type |

Blue semiconductor laser |

||

|

wavelength |

405nm (visible light) |

|||

|

Laser class |

Class 2 laser products |

|||

|

output |

4.8mW |

|||

|

Spot shape (reference distance) |

Approximately 48 mm x 48 µm |

|||

|

Repeat accuracy |

Z axis (height) |

0.5µm * 2 * 3 |

||

|

X-axis (width) |

10µm * 2 * 4 |

|||

|

Straightness |

Z axis (height) |

± 0.1% of FS * 5 |

||

|

Profile data interval |

X-axis (width) |

50µm |

||

|

Sampling cycle (trigger interval) |

Fastest 16µs (high-speed mode), fastest 32µs (high-performance mode) * 6 |

|||

|

Temperature characteristics |

0.01% of FS / ℃ |

|||

|

Environmental resistance |

Protective structure |

IP67 (IEC60529) * 7 |

||

|

Ambient illuminance used |

Incandescent lamp: 10,000 lux or less * 8 |

|||

|

Operating ambient temperature |

0 to + 45 ℃ * 9 |

|||

|

Operating ambient humidity |

20-85% RH (no condensation) |

|||

|

Vibration resistant |

10-57 Hz, double amplitude 1.5 mm, X, Y, Z 3 hours in each direction |

|||

|

Impact resistance |

15 G / 6 ms |

|||

|

Material |

Aluminum |

|||

|

mass |

About 400 g |

|||

|

* 1 Classification is carried out according to IEC60825-1 according to Laser Notice No.50 of FDA (CDRH). |

||||

|

Model |

LJ-V7200 |

|||

|

Installation condition |

Diffuse reflection |

|||

|

Reference distance |

200mm |

|||

|

Measurement range |

Z axis (height) |

± 48mm (FS = 96mm) |

||

|

X axis (width) |

NEAR side |

51mm |

||

|

Reference distance |

62mm |

|||

|

FAR side |

73mm |

|||

|

light source |

type |

Blue semiconductor laser |

||

|

wavelength |

405nm (visible light) |

|||

|

Laser class |

Class 2 laser products |

|||

|

output |

4.8mW |

|||

|

Spot shape (reference distance) |

Approximately 90 mm x 85 µm |

|||

|

Repeat accuracy |

Z axis (height) |

1µm * 2 * 3 |

||

|

X-axis (width) |

20µm * 2 * 4 |

|||

|

Straightness |

Z axis (height) |

± 0.1% of FS * 5 |

||

|

Profile data interval |

X-axis (width) |

100µm |

||

|

Sampling cycle (trigger interval) |

Fastest 16µs (high-speed mode), fastest 32µs (high-performance mode) * 6 |

|||

|

Temperature characteristics |

0.01% of FS / ℃ |

|||

|

Environmental resistance |

Protective structure |

IP67 (IEC60529) * 7 |

||

|

Ambient illuminance used |

Incandescent lamp: 10,000 lux or less * 8 |

|||

|

Operating ambient temperature |

0 to + 45 ℃ * 9 |

|||

|

Operating ambient humidity |

20-85% RH (no condensation) |

|||

|

Vibration resistant |

10-57 Hz, double amplitude 1.5 mm, X, Y, Z 3 hours in each direction |

|||

|

Impact resistance |

15 G / 6 ms |

|||

|

Material |

Aluminum |

|||

|

mass |

About 550 g |

|||

|

* 1 Classification is carried out according to IEC60825-1 according to Laser Notice No.50 of FDA (CDRH). |

||||

| Model | LJ-V7300 | |||

| Installation condition | Diffuse reflection | |||

| Reference distance | 300mm | |||

| Measurement range | Z axis (height) | ± 145mm (FS = 290mm) | ||

| X axis (width) | NEAR side | 110mm | ||

| Reference distance | 180mm | |||

| FAR side | 240mm | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2 laser products (IEC60825-1, FDA (CDRH) Part 1040.10 * 1 ) |

|||

| output | 4.8mW | |||

| Spot shape (reference distance) | Approximately 240 mm x 610 µm | |||

| Repeat accuracy | Z axis (height) | 5µm * 2 * 3 | ||

| X-axis (width) | 60µm * 2 * 4 | |||

| Straightness | Z axis (height) | ± 0.05 to ± 0.15% of FS * 5 * 6 | ||

| Profile data interval | X-axis (width) | 300µm | ||

| Sampling cycle (trigger interval) | Fastest 16µs (high-speed mode), fastest 32µs (high-performance mode) * 7 | |||

| Temperature characteristics | 0.01% of FS / ℃ | |||

| Environmental resistance | Protective structure | IP67 (IEC60529) * 8 | ||

| Ambient illuminance used | Incandescent lamp: 10,000 lux or less * 9 | |||

| Operating ambient temperature | 0 to +45 ℃ * 10 | |||

| Operating ambient humidity | 20-85% RH (no condensation) | |||

| Vibration resistant | 10-57 Hz, double amplitude 1.5 mm, X, Y, Z 3 hours in each direction | |||

| Impact resistance | 15 G / 6 ms | |||

| Material | Aluminum | |||

| mass | About 1,000 g | |||

| * 1 Classification is carried out according to IEC60825-1 according to Laser Notice No.50 of FDA (CDRH). * 2 Value when measured at an average of 4096 times at the reference distance. * 3 The measurement target is our standard target. The value when the average height of the initial setting area is measured in the height mode. Others are default settings. * 4 The object to be measured is a pin gauge. The value when the intersection position between the pin gauge R surface and the edge level is measured in the position mode. Others are default settings. * 5 Linearity varies depending on the measurement area. * 6 The measurement target is our standard target. Profile data when measured with smoothing 64 times and averaging 8 times. Others are default settings. * 7 In high-speed mode, when the measurement range is minimum, binning is ON, imaging mode is standard, and parallel imaging is ON. Others are default settings. In the high-performance mode, when the measurement range is the minimum, binning is ON, and the imaging mode is standard. Others are default settings. * 8 Value when a head cable (CB-B *) or extension cable (CB-B * E) is connected. * 9 Illuminance on the light receiving surface of the sensor head when light is applied to the blank paper when measuring blank paper. * 10 The head must be attached to a metal plate for use. |

||||

|

Model |

LJ-V7001P |

|||

|

Number of connectable sensors |

Max. 2 units |

|||

|

Display |

Minimum |

0.1 µm, 0.00001 mm2, 0.01° |

||

|

Maximum display range |

±9999.99 mm 393.7″, ±9999.99 mm2 |

|||

|

Input terminal block |

Laser remote interlock input |

No-voltage input*1 |

||

|

Input |

Encoder input |

NPN open collector output/PNP open collector output (5V / 12V / 24V) line driver output |

||

|

Input terminal block |

Trigger input |

Voltage input*2 |

||

|

Timing 1,2 input |

||||

|

Auto-zero 1,2 input |

||||

|

Input |

Reset 1, 2 input |

|||

|

Input terminal |

Start measurement/stop input |

|||

|

Start storage/stop input |

||||

|

Clear memory input |

||||

|

Laser OFF input |

||||

|

Program switch input |

Voltage input x 4 inputs*2 |

|||

|

Output terminal block |

Analog voltage output |

±10 V x 2 outputs, Output impedance: 100 Ω |

||

|

Output |

OUT comparator output |

PNP open collector output x 12 outputs*3 |

||

|

Strobe output |

PNP open collector output*3 |

|||

|

Disable trigger output |

||||

|

Memory FULL output |

||||

|

Ready output |

||||

|

Output terminal block |

Error output |

PNP open collector output (N.C.)*3 |

||

|

PC interface |

Ethernet |

1000BASE-T/100BASE-TX*4 |

||

|

USB |

USB 2.0 high speed compliant (USB 1.1 Full-SPEED compatible)*4 |

|||

|

RS232C |

Measurement data output and control I/O (Can select a baud rate of up to 115,200 bits/s) |

|||

|

Rating |

Power voltage |

24 VDC ±10 %, including Ripple (P-P) |

||

|

Current consumption |

1.3 A or less when connected to 1 head |

|||

|

Environmental resistance |

Ambient temperature |

0 to +50 °C 32 to 122 °F |

||

|

Relative humidity |

20 to 85 % RH (No condensation) |

|||

|

Weight |

Approx. 1,500 g |

|||

|

*1 The rating for non-voltage input is up to 1 V for ON voltage and up to 0.6 mA for OFF current |

||||