LJ-X Lazer Profil Ölçüm Sensörü

Tüm Hedefleri Yüksek Hassasiyetle Ölçün

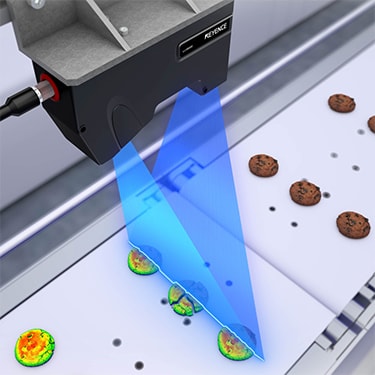

Yüksek Çözünürlüklü Hat İçi Ölçüm

• Ultra yüksek hassasiyet

• Her tip malzeme ile uyumlu

• 3 adımda kolay kurulum

2D/3D Lazer Profil Ölçüm Sensörü

LJ-X Lazer Profil Ölçüm Sensörü

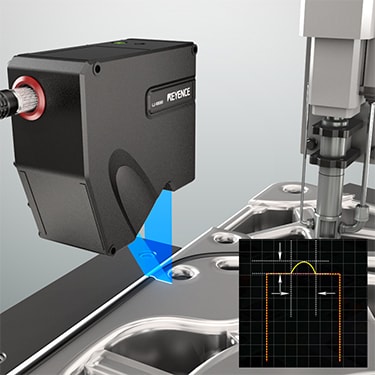

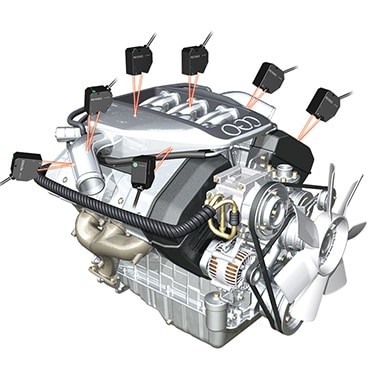

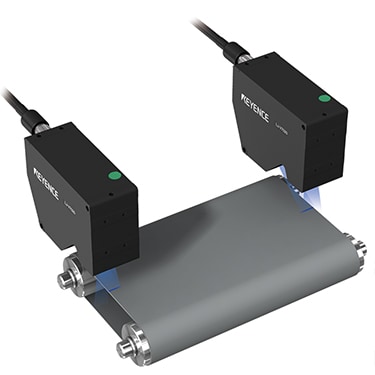

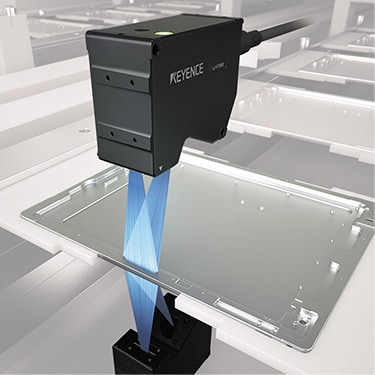

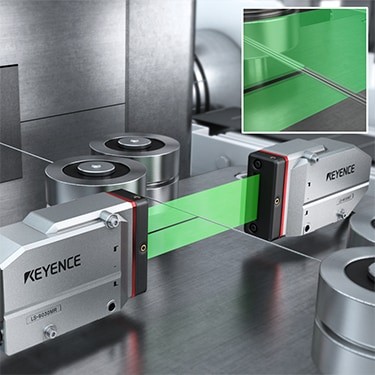

LJ-X Lazer Profil Ölçüm Sensörü ile 2D/3D ölçüm ve denetim gerçekleştirin. Çok yönlü lazer profil sensörü, 3200 nokta/profil sunarak herhangi bir şekli veya malzemeyi yüksek çözünürlüklü görüntüler ile kararlı bir şekilde ölçer. LJ-X Lazer Profil Ölçüm Sensörü dört farklı kontrolcü opsiyonuyla uyumludur ve kullanıcıların sistem kapasitesini herhangi bir uygulama gereksinimiyle mükemmel şekilde hizalayan bir kurulum seçmesine olanak tanır.

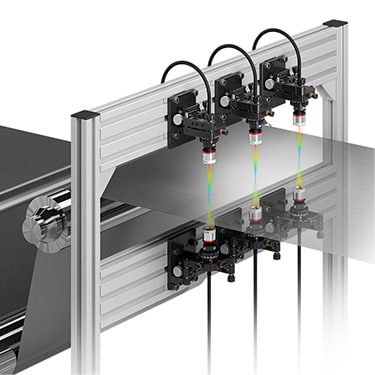

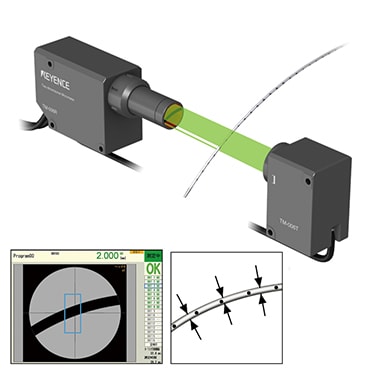

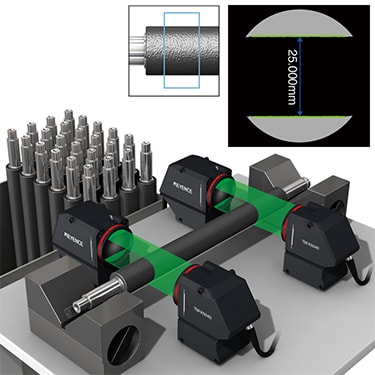

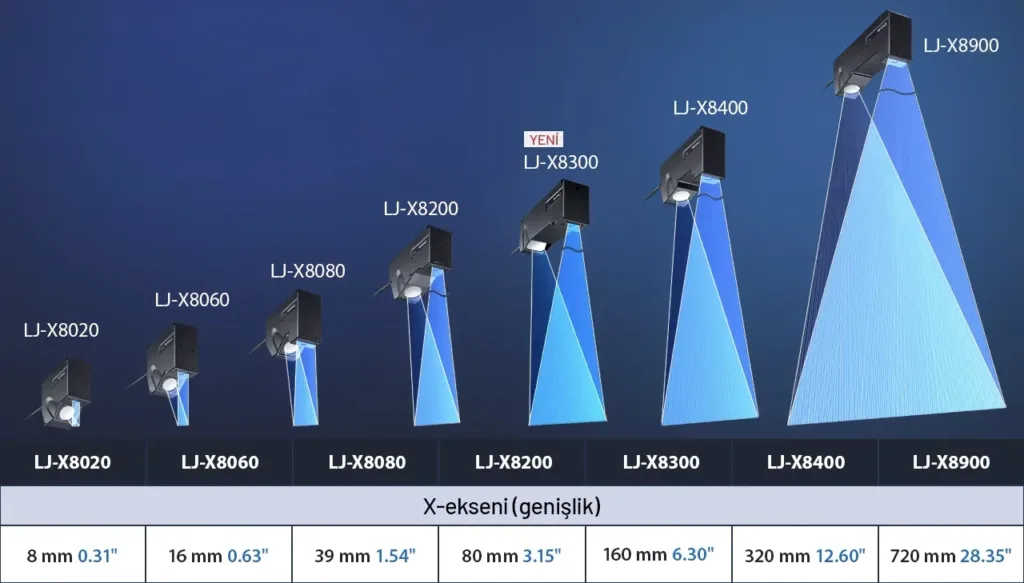

Maksimum lazer çizgi genişliği 720 mm’nin (28 inç) üzerine çıkar ve daha da büyük hedefleri taramak için birden fazla eşleştirilebilir. Bu yüksek performanslı lazer profil sensörlerin programlanması üç basit adımda tamamlanır, bu da her deneyim seviyesinden kullanıcı için doğru hat içi 3D ölçümü erişilebilir hale getirir.

Entek’e Sor | +90 850 201 41 41

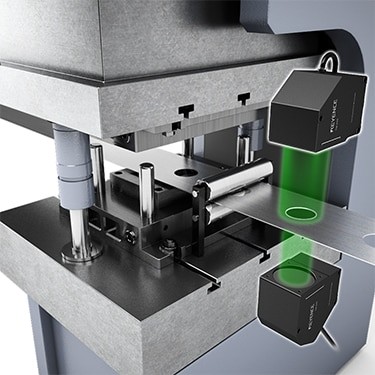

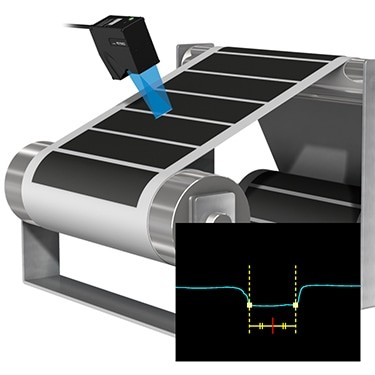

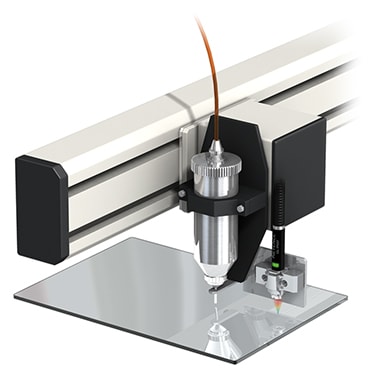

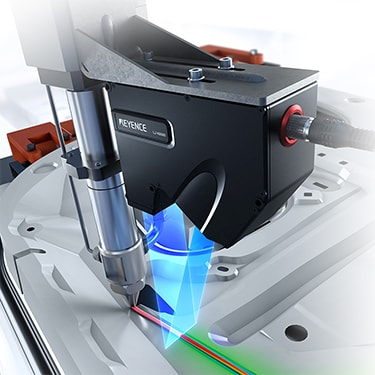

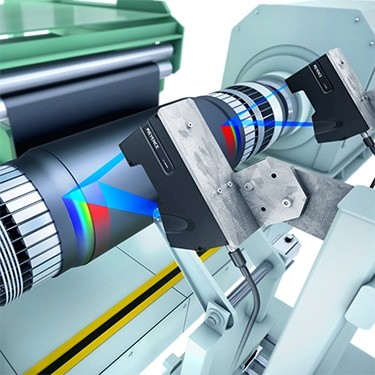

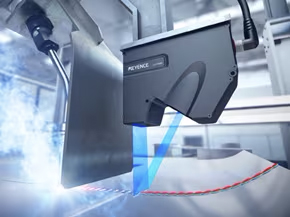

Kaynak Kalite Kontrolü

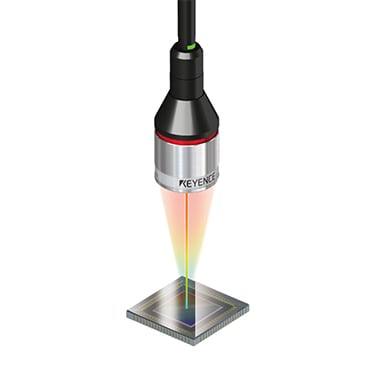

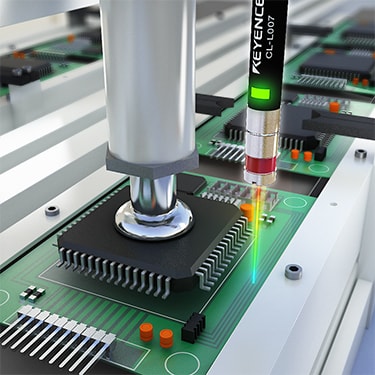

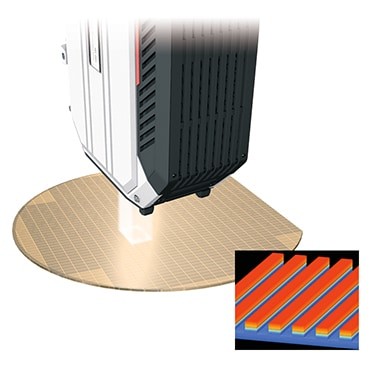

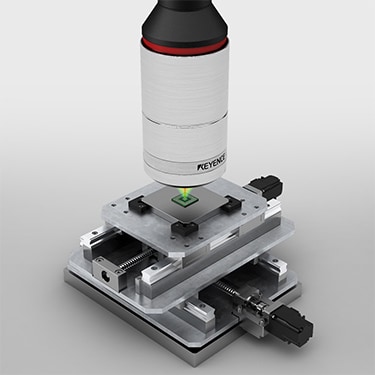

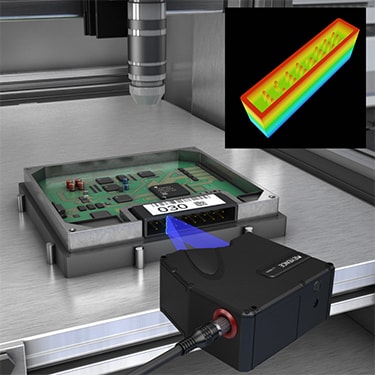

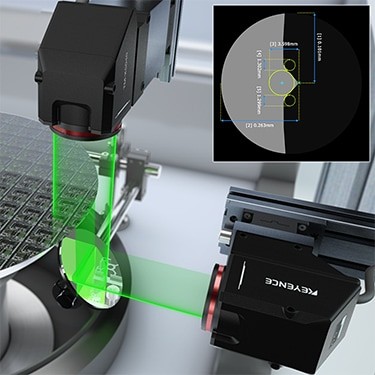

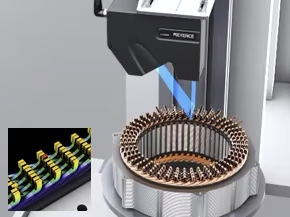

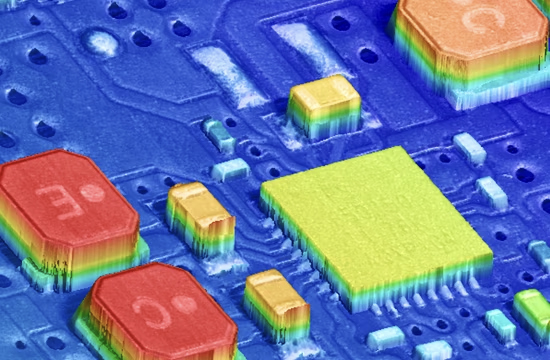

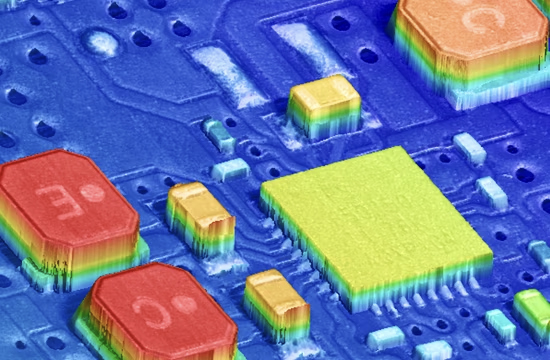

Terminal Eğimi ve Yükseklik Ölçümü

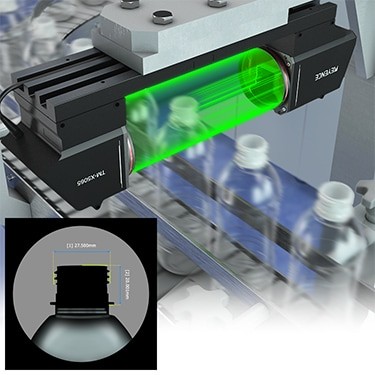

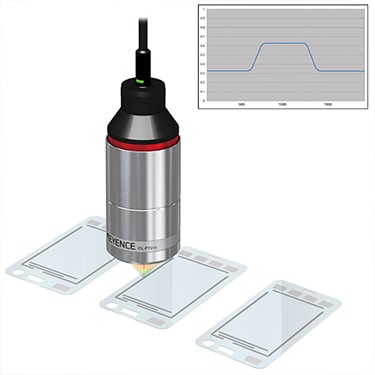

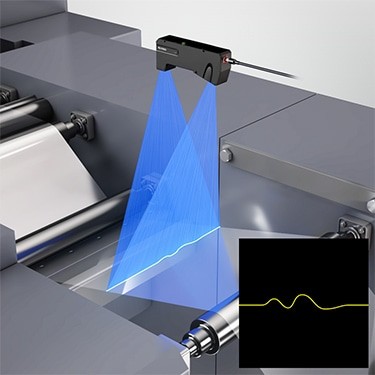

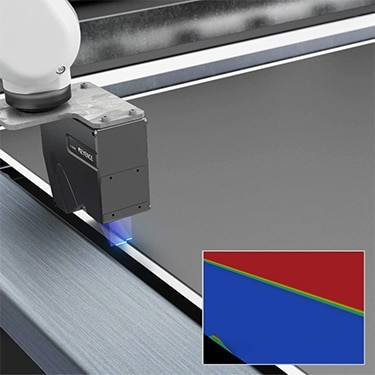

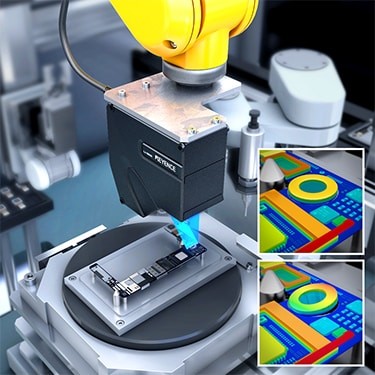

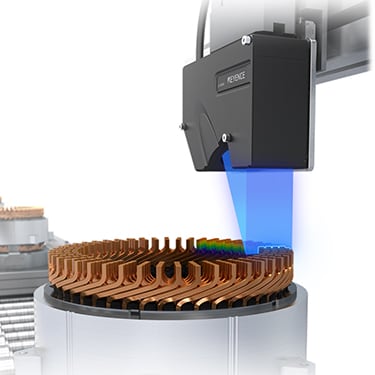

360° Yüzey Kontrolü

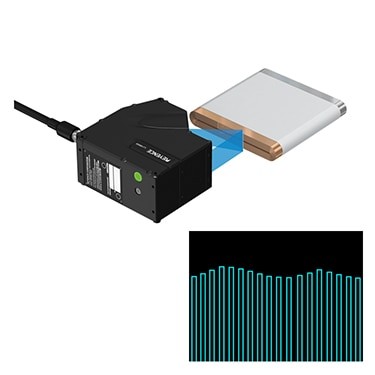

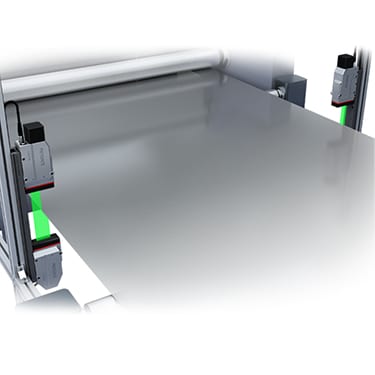

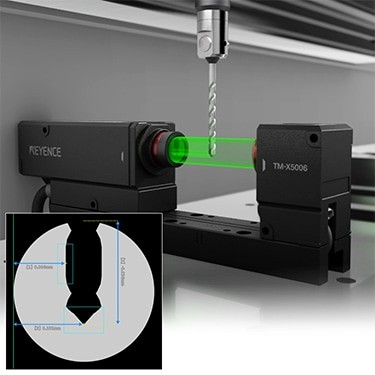

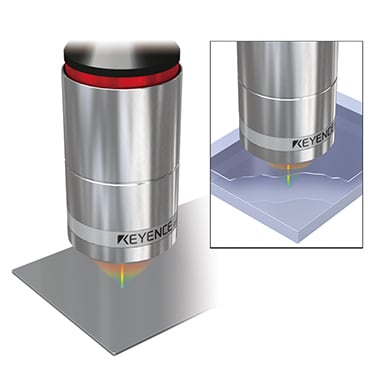

Terminal Yükseklik Ölçümü

Özellikler

4x Daha Fazla Çözünürlük ile Güvenilirliği Artırın

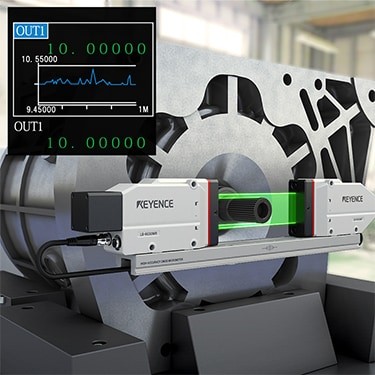

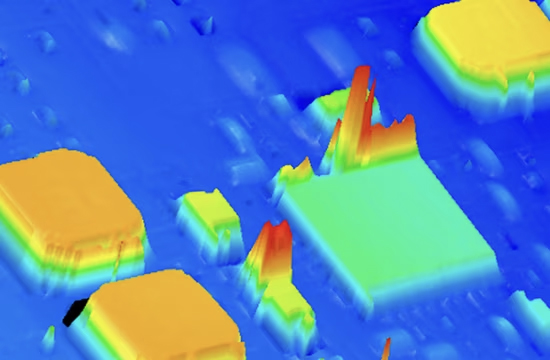

Bir hedefin gerçek şeklini yakalamak, güvenilir denetimler gerçekleştirmek için kritik öneme sahiptir. LJ-X Lazer Profil Ölçüm Sensörü LJ-X8000 Serisi, 3200 nokta/profil ile hedefin şeklini yüksek çözünürlükte yakalayarak hat üzerinde doğru ölçüm yapılmasını mümkün kılar.

• Taslak

• Düzensiz

• Yüzeye bağlı

• Detaylı

• Tutarlı

• Her yüzeyde stabil

Yüksek Hassasiyet 3200 nokta/profil

En Üst Seviyede Çözünürlük ve Hata Tespiti

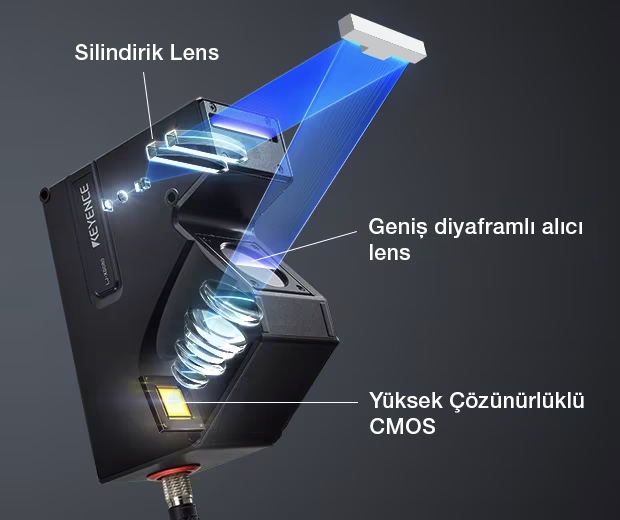

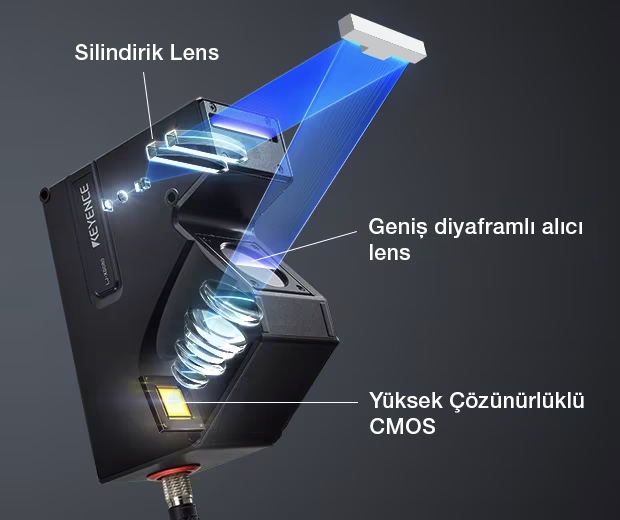

Sensörün çözünürlüğünü iyileştirmek için CMOS üzerindeki piksel sayısının artırılması gerekir. Bu, her bir pikseli daha küçük hale getirerek gerçekleştirilebilir; ancak daha küçük pikseller yetersiz ışık algılamasına neden olarak bazı hedeflerde hatalı profile yol açabilir. LJ-X Lazer Profil Ölçüm Sensörü için, herhangi bir hedef üzerinde yüksek çözünürlüklü ölçüm yapabilen bir lazer profil sensörü oluşturmak üzere yeni bir teknoloji uygulanır.

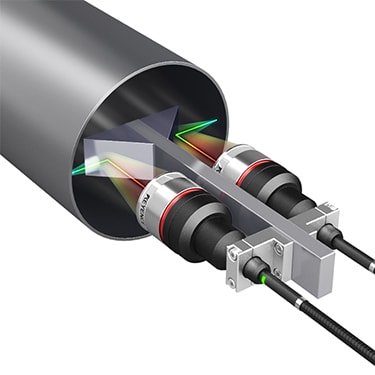

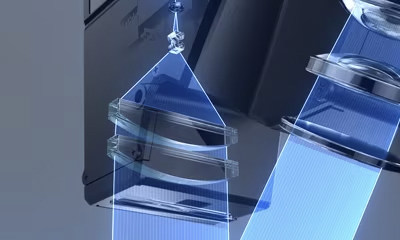

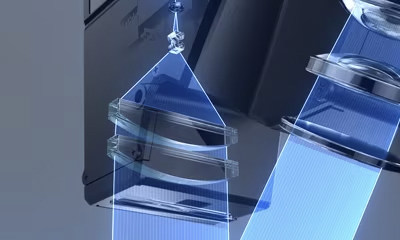

Silindirik Lens

Paralel ışık, yansıyan ışığın hedefin yüzeyi boyunca dağılmasını önlemek için tasarlanmış silindirik bir lens kullanılarak yayılır. Bu, herhangi bir şekil veya yüzeyden güvenilir yansımalar oluşturur.

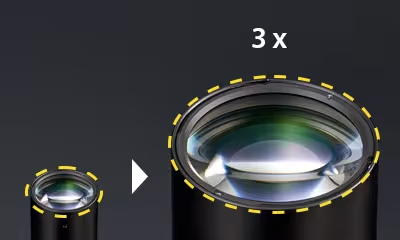

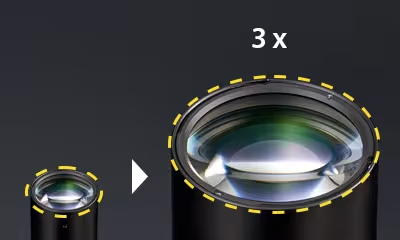

Geniş diyaframlı alıcı Lens

Sensör, geleneksel modellere göre 3 kat daha fazla alana sahip olan ve alınan ışık yoğunluğunu artıran bir alıcı lens ile donatılmıştır. Bu, sensörün her ortamda istikrarlı profiller üretmesini sağlar.

Yüksek Çözünürlüklü CMOS

Bu yeni geliştirilen CMOS, 3200 nokta/profil kullanarak yüksek çözünürlüklü ölçüm sağlarken, farklı yansıtma özelliklerine sahip hedeflerde gelişmiş görüntüleme kabiliyeti sunar.

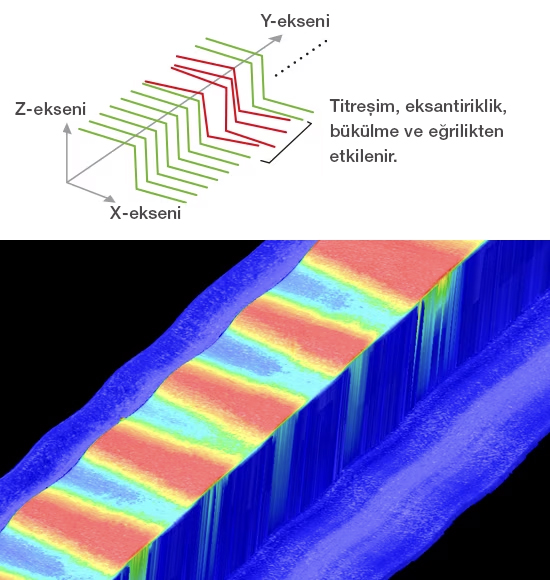

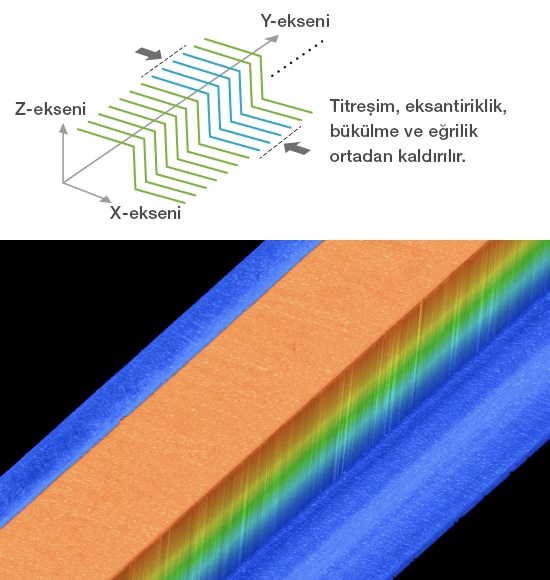

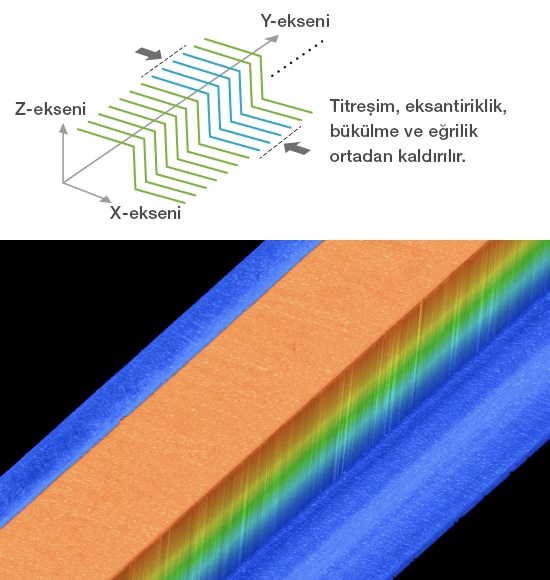

Profil Hizalama Fonksiyonu

3D görüntü oluşturulurken, her 2D profilin konumu X, Z ve θ eksenlerinde ayarlanır. Bu, titreşim ve eksantrikliğin yanı sıra hedefteki bükülme ve eğriliğin etkisini ortadan kaldırarak denetim için en uygun görüntüyü oluşturur.

Her Türlü Uygulama Gereksinimini Karşılamak Üzere Tasarlanmış Ürün Yelpazesinden Seçim Yapın

LJ-X Lazer Profil Ölçüm Sensörü, her sektörde kalite kontrolü ve süreç iyileştirmeyi desteklemek için geniş bir sensör yelpazesi sunar.

İletişim

Teknik Özellikler

- LJ-X8020

- LJ-X8060

- LJ-X8080

- LJ-X8200

- LJ-X8300

- LJ-X8400

- LJ-X8900

| Model | LJ-X8020 | |||

| Reference distance | 20 mm 0.79″ | |||

| Measurement range | Z axis (height) | ±2.2 mm 0.09″ (F.S.=4.4 mm 0.17″) | ||

| X axis (width) | NEAR side | 7 mm 0.28″ | ||

| Reference distance | 7.5 mm 0.30″ | |||

| FAR side | 8 mm 0.31″ | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2M laser product (IEC60825-1, FDA (CDRH) Part 1040.10 *1) *2 | |||

| output | 10mW | |||

| Spot size | Approx. 16 mm × 32 μm 0.63″ × 0.0013″ (reference distance) | |||

| Repeatability | Z axis (height) | 0.3 μm 0.000012″ *3*4 | ||

| X-axis (width) | 0.3 μm 0.000012″ *3*5 | |||

| Linearity | Z axis (height) | ±0.05% of F.S. (±0.012%) *6 | ||

| Profile data interval | X-axis (width) | 2.5 μm 0.000098″ (2 μm 0.000079″~) *7 | ||

| Profile data count | 3200 points | |||

| HDR (high dynamic range) | Single-shot HDR *8 | |||

| Laser irradiation position confirmation function | Light source | Blue LED (405 nm) | ||

| Temperature characteristic | 0.01% of F.S./°C | |||

| Environmental resistance | Enclosure rating | IP67 (IEC60529) * 9 | ||

| Ambient light | Incandescent lamp: 10,000 lux or less * 10 | |||

| Ambient temperature | 0 to +45°C 32 to +113°F *11 | |||

| Relative humidity | 85% RH or less (no condensation) | |||

| Vibration resistance | 10 to 57 Hz, double amplitude 1.5 mm 0.06″; 3 hours each for X, Y, and Z axes | |||

| Shock resistance | 15 G / 6 msec | |||

| Material | Aluminum | |||

| Weight | Approx. 1000 g 2.20 lb | |||

| Model | LJ-X8060 | |||

| Reference distance | 64 mm 2.52″ | |||

| Measurement range | Z axis (height) | ±7.3 mm 0.29″ (F.S.=14.6 mm 0.57″) | ||

| X axis (width) | NEAR side | 15 mm 0.59″ | ||

| Reference distance | 16 mm 0.63″ | |||

| FAR side | 16 mm 0.63″ | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2M laser product (IEC60825-1, FDA (CDRH) Part 1040.10 *1) *2 | |||

| output | 10mW | |||

| Spot size | Approx. 25 mm × 49 μm 0.98″ × 0.0019″ (reference distance) | |||

| Repeatability | Z axis (height) | 0.4 μm 0.000012″ *3*4 | ||

| X-axis (width) | 0.5 μm 0.000012″ *3*5 | |||

| Linearity | Z axis (height) | ±0.04% of F.S. (±0.008%) *6 | ||

| Profile data interval | X-axis (width) | 5 μm 0.000197″ (4 μm 0.000157″~) *7 | ||

| Profile data count | 3200 points | |||

| HDR (high dynamic range) | Single-shot HDR *8 | |||

| Laser irradiation position confirmation function | Light source | Blue LED (405 nm) | ||

| Temperature characteristic | 0.01% of F.S./°C | |||

| Environmental resistance | Enclosure rating | IP67 (IEC60529) * 9 | ||

| Ambient light | Incandescent lamp: 10,000 lux or less * 10 | |||

| Ambient temperature | 0 to +45°C 32 to +113°F *11 | |||

| Relative humidity | 85% RH or less (no condensation) | |||

| Vibration resistance | 10 to 57 Hz, double amplitude 1.5 mm 0.06″; 3 hours each for X, Y, and Z axes | |||

| Shock resistance | 15 G / 6 msec | |||

| Material | Aluminum | |||

| Weight | Approx. 1000 g 2.20 lb | |||

| Model | LJ-X8080 | |||

| Reference distance | 73 mm 2.87″ | |||

| Measurement range | Z axis (height) | ±20.5 mm 0.81″ (F.S.=41 mm 1.61″) | ||

| X axis (width) | NEAR side | 30 mm 1.18″ | ||

| Reference distance | 35 mm 1.38″ | |||

| FAR side | 39 mm 1.54″ | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2M laser product (IEC60825-1, FDA (CDRH) Part 1040.10 *1) *2 | |||

| output | 10mW | |||

| Spot size | Approx. 44 mm × 72 μm 1.73″ × 0.0028″ (reference distance) | |||

| Repeatability | Z axis (height) | 0.5 μm 0.000020″ *3*4 | ||

| X-axis (width) | 1.0 μm 0.000039″ *3*5 | |||

| Linearity | Z axis (height) | ±0.04% of F.S. (±0.008%) *6 | ||

| Profile data interval | X-axis (width) | 12.5 μm 0.0005″ (10 μm 0.0004″~) *7 | ||

| Profile data count | 3200 points | |||

| HDR (high dynamic range) | Single-shot HDR *8 | |||

| Laser irradiation position confirmation function | Light source | Blue LED (405 nm) | ||

| Temperature characteristic | 0.01% of F.S./°C | |||

| Environmental resistance | Enclosure rating | IP67 (IEC60529) * 9 | ||

| Ambient light | Incandescent lamp: 10,000 lux or less * 10 | |||

| Ambient temperature | 0 to +45°C 32 to +113°F *11 | |||

| Relative humidity | 85% RH or less (no condensation) | |||

| Vibration resistance | 10 to 57 Hz, double amplitude 1.5 mm 0.06″; 3 hours each for X, Y, and Z axes | |||

| Shock resistance | 15 G / 6 msec | |||

| Material | Aluminum | |||

| Weight | Approx. 1100 g 2.43 lb | |||

| Model | LJ-X8200 | |||

| Reference distance | 245 mm 9.65″ | |||

| Measurement range | Z axis (height) | ±34 mm 1.34″ (F.S.=68 mm 2.68″) | ||

| X axis (width) | NEAR side | 64 mm 2.52″ | ||

| Reference distance | 72 mm 2.83″ | |||

| FAR side | 80 mm 3.15″ | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2M laser product (IEC60825-1, FDA (CDRH) Part 1040.10 *1) *2 | |||

| output | 10mW | |||

| Spot size | Approx. 115 mm × 116 μm 4.53″ × 0.0046″ (reference distance) | |||

| Repeatability | Z axis (height) | 1 μm 0.000039″ *3*4 | ||

| X-axis (width) | 3 μm 0.000118″ *3*5 | |||

| Linearity | Z axis (height) | ±0.04% of F.S. (±0.006%) *6 | ||

| Profile data interval | X-axis (width) | 25 μm 0.0010″ (20 μm 0.0008″~) *7 | ||

| Profile data count | 3200 points | |||

| HDR (high dynamic range) | Single-shot HDR *8 | |||

| Laser irradiation position confirmation function | Light source | Blue LED (405 nm) | ||

| Temperature characteristic | 0.01% of F.S./°C | |||

| Environmental resistance | Enclosure rating | IP67 (IEC60529) * 9 | ||

| Ambient light | Incandescent lamp: 10,000 lux or less * 10 | |||

| Ambient temperature | 0 to +45°C 32 to +113°F *11 | |||

| Relative humidity | 85% RH or less (no condensation) | |||

| Vibration resistance | 10 to 57 Hz, double amplitude 1.5 mm 0.06″; 3 hours each for X, Y, and Z axes | |||

| Shock resistance | 15 G / 6 msec | |||

| Material | Aluminum | |||

| Weight | Approx. 1200 g 2.65 lb | |||

| Model | LJ-X8300 | |||

| Reference distance | 288 mm 11.34″ | |||

| Measurement range | Z axis (height) | ±53 mm 2.09″ (F.S.=106 mm 4.17″) | ||

| X axis (width) | NEAR side | 134 mm 5.28″ | ||

| Reference distance | 72 mm 2.83″ | |||

| FAR side | 80 mm 3.15″ | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2M laser product (IEC60825-1, FDA (CDRH) Part 1040.10 *1) *2 | |||

| output | 10mW | |||

| Spot size | Approx. 115 mm × 116 μm 4.53″ × 0.0046″ (reference distance) | |||

| Repeatability | Z axis (height) | 1 μm 0.000039″ *3*4 | ||

| X-axis (width) | 3 μm 0.000118″ *3*5 | |||

| Linearity | Z axis (height) | ±0.04% of F.S. (±0.006%) *6 | ||

| Profile data interval | X-axis (width) | 25 μm 0.0010″ (20 μm 0.0008″~) *7 | ||

| Profile data count | 3200 points | |||

| HDR (high dynamic range) | Single-shot HDR *8 | |||

| Laser irradiation position confirmation function | Light source | Blue LED (405 nm) | ||

| Temperature characteristic | 0.01% of F.S./°C | |||

| Environmental resistance | Enclosure rating | IP67 (IEC60529) * 9 | ||

| Ambient light | Incandescent lamp: 10,000 lux or less * 10 | |||

| Ambient temperature | 0 to +45°C 32 to +113°F *11 | |||

| Relative humidity | 85% RH or less (no condensation) | |||

| Vibration resistance | 10 to 57 Hz, double amplitude 1.5 mm 0.06″; 3 hours each for X, Y, and Z axes | |||

| Shock resistance | 15 G / 6 msec | |||

| Material | Aluminum | |||

| Weight | Approx. 1200 g 2.65 lb | |||

| Model | LJ-X8400 | |||

| Reference distance | 380 mm 14.96″ | |||

| Measurement range | Z axis (height) | ±60 mm ±2.36″ (+95 to -220 mm +3.74″ to -8.66″ *12) (F.S.=315 mm 12.40″) | ||

| X axis (width) | NEAR side | 180 mm 7.09″ (163 mm 6.42″ *12) | ||

| Reference distance | 210 mm 8.27″ | |||

| FAR side | 240 mm 9.45″ (320 mm 12.60″ *12) | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2M laser product (IEC60825-1, FDA (CDRH) Part 1040.10 *1) *2 | |||

| output | 10mW | |||

| Spot size | Approx. 275 mm × 249 μm 10.83″ × 0.0098″ (reference distance) | |||

| Repeatability | Z axis (height) | 5 μm 0.000197″ *3*4 | ||

| X-axis (width) | 10 μm 0.0004″ *3*5 | |||

| Linearity | Z axis (height) | Reference distance: ±60 mm ±2.36″ ±0.025% of F.S. (±0.003%) Total range: ±0.035% of F.S. (±0.005%) *6 |

||

| Profile data interval | X-axis (width) | 275 μm 0.0030″ (50 μm 0.0020″~) 100 μm 0.0039″ (50 μm 0.0020″~) *12 *7 |

||

| Profile data count | 3200 points | |||

| HDR (high dynamic range) | Single-shot HDR *8 | |||

| Laser irradiation position confirmation function | Light source | Blue LED (405 nm) | ||

| Temperature characteristic | 0.01% of F.S./°C | |||

| Environmental resistance | Enclosure rating | IP67 (IEC60529) * 9 | ||

| Ambient light | Incandescent lamp: 10,000 lux or less * 10 | |||

| Ambient temperature | 0 to +45°C 32 to +113°F *11 | |||

| Relative humidity | 85% RH or less (no condensation) | |||

| Vibration resistance | 10 to 57 Hz, double amplitude 1.5 mm 0.06″; 3 hours each for X, Y, and Z axes | |||

| Shock resistance | 15 G / 6 msec | |||

| Material | Aluminum | |||

| Weight | Approx. 1300 g 2.87 lb | |||

| Model | LJ-X8900 | |||

| Reference distance | 980 mm 38.58″ | |||

| Measurement range | Z axis (height) | ±400 mm 15.75″ (F.S.=800 mm 31.50″) | ||

| X axis (width) | NEAR side | 300 mm 11.81″ | ||

| Reference distance | 510 mm 20.08″ | |||

| FAR side | 720 mm 28.35″ | |||

| light source | type | Blue semiconductor laser | ||

| wavelength | 405nm (visible light) | |||

| Laser class | Class 2M laser product (IEC60825-1, FDA (CDRH) Part 1040.10 *1) *2 | |||

| output | 10mW | |||

| Spot size | Approx. 622 mm × 566 μm 24.49″ × 0.0223″ (reference distance) | |||

| Repeatability | Z axis (height) | 10 μm 0.0004″ *3*4 | ||

| X-axis (width) | 25 μm 0.0010″ *3*5 | |||

| Linearity | Z axis (height) | Near~reference: distance ±0.015% of F.S. (±0.004%) Total range: ±0.05% of F.S. (±0.006%) *6 |

||

| Profile data interval | X-axis (width) | 225 μm 0.0089″ (100 μm 0.0039″~) *7 | ||

| Profile data count | 3200 points | |||

| HDR (high dynamic range) | Single-shot HDR *8 | |||

| Laser irradiation position confirmation function | Light source | Blue LED (405 nm) | ||

| Temperature characteristic | 0.01% of F.S./°C | |||

| Environmental resistance | Enclosure rating | IP67 (IEC60529) * 9 | ||

| Ambient light | Incandescent lamp: 10,000 lux or less * 10 | |||

| Ambient temperature | 0 to +45°C 32 to +113°F *11 | |||

| Relative humidity | 85% RH or less (no condensation) | |||

| Vibration resistance | 10 to 57 Hz, double amplitude 1.5 mm 0.06″; 3 hours each for X, Y, and Z axes | |||

| Shock resistance | 15 G / 6 msec | |||

| Material | Aluminum | |||

| Weight | Approx. 1600 g 3.53 lb | |||

Ek Bilgi

- *1 Classification performed based on IEC60825-1 in accordance with FDA (CDRH) Laser Notice No. 56.

- *2 Do not view the beam directly using optical instruments (such as eye loupes, magnifiers, microscopes, telescopes, or binoculars). Observing the laser output using optical instruments is dangerous and may damage the eyes.

- *3 Values measured by averaging 4096 times at the reference distance.

- *4 The measured target is a KEYENCE standard target. Value when the average height of the default setting area is measured with height and position tools. All other settings are default values.

- *5 The measured target is a pin gauge. Value when the point of intersection for the pin gauge rounded surface and edge level is measured using height and position tools. All other settings are default values.

- *6 Profile data when measured by smoothing 64 times and averaging 8 times. All other settings are default values. Values inside parentheses are representative examples of averages for all profile data.

- *7 The profile data interval can be changed. If changed, the measurement range in the X direction will also change.

- *8 A characteristic that allows for stable, high-precision measurement with a single capture (exposure) at all levels of reflectance, from black (low) to glossy surfaces (high).

- *9 The value when a head cable (CB-B*) or extension cable (CB-B*E) is connected. Does not include CB-B**L connection.

- *10 When measuring white paper, illuminance on the sensor head receiving surface when light is applied to white paper.

- *11 The head needs to be mounted to a metal plate to be used.

- *12 When range is extended.